Semi-Automatic Drum Liquid Chemical Filling Machine for 200L Latex Paint

Semi-Automatic Drum Liquid Chemical Filling Machine for 200L Latex Paint

Overview

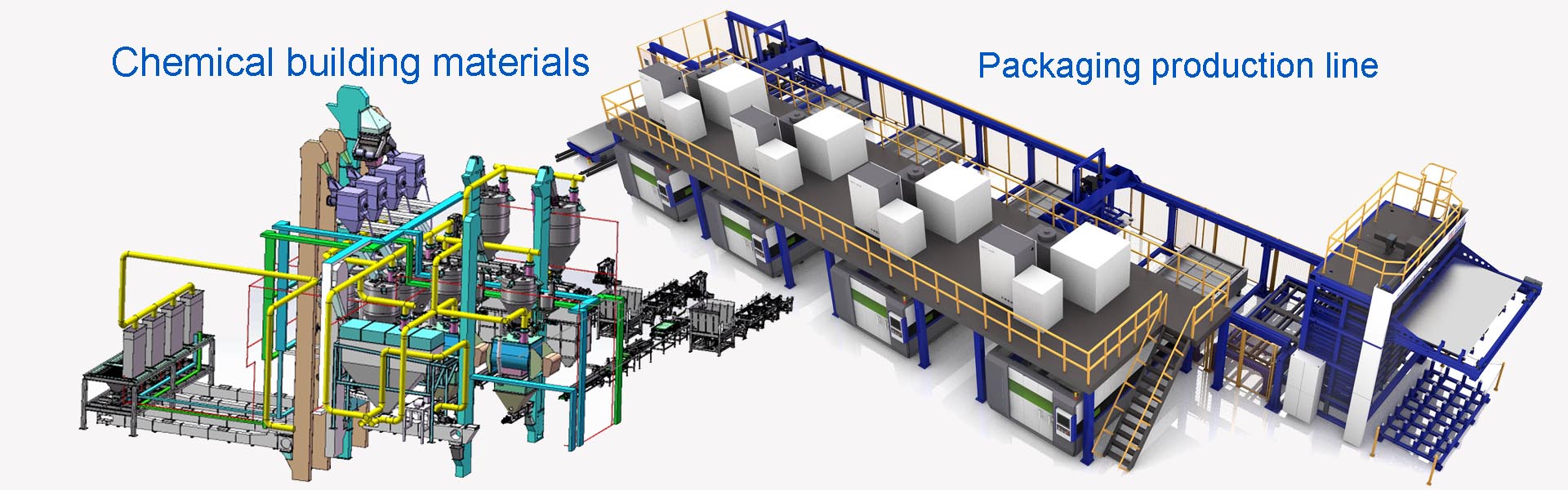

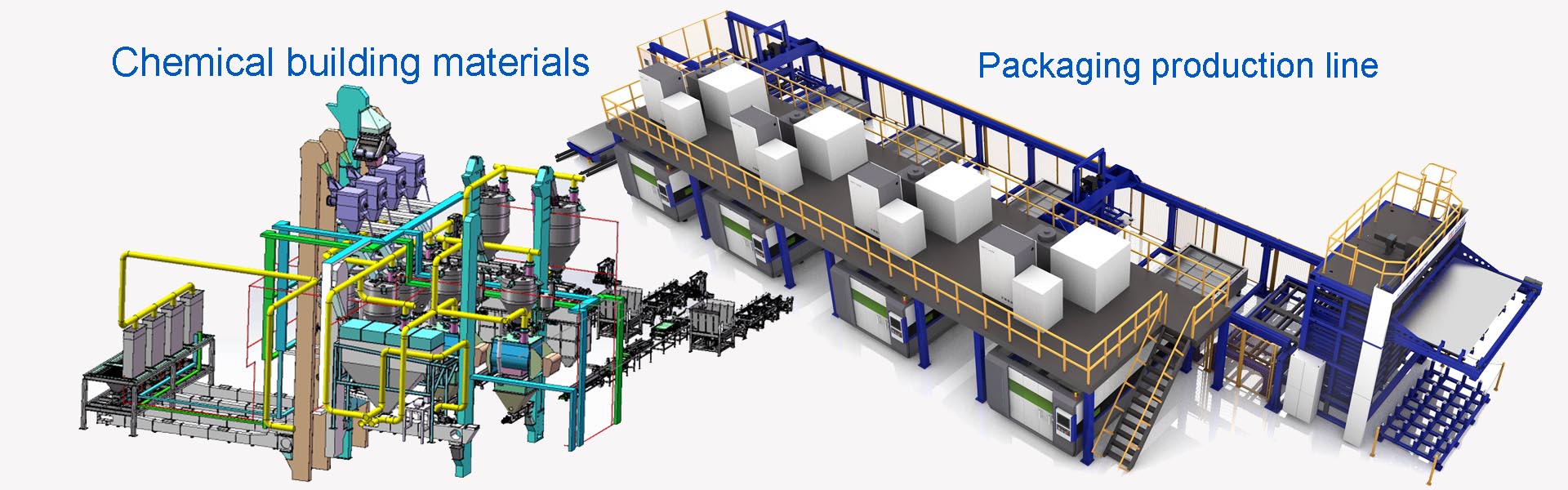

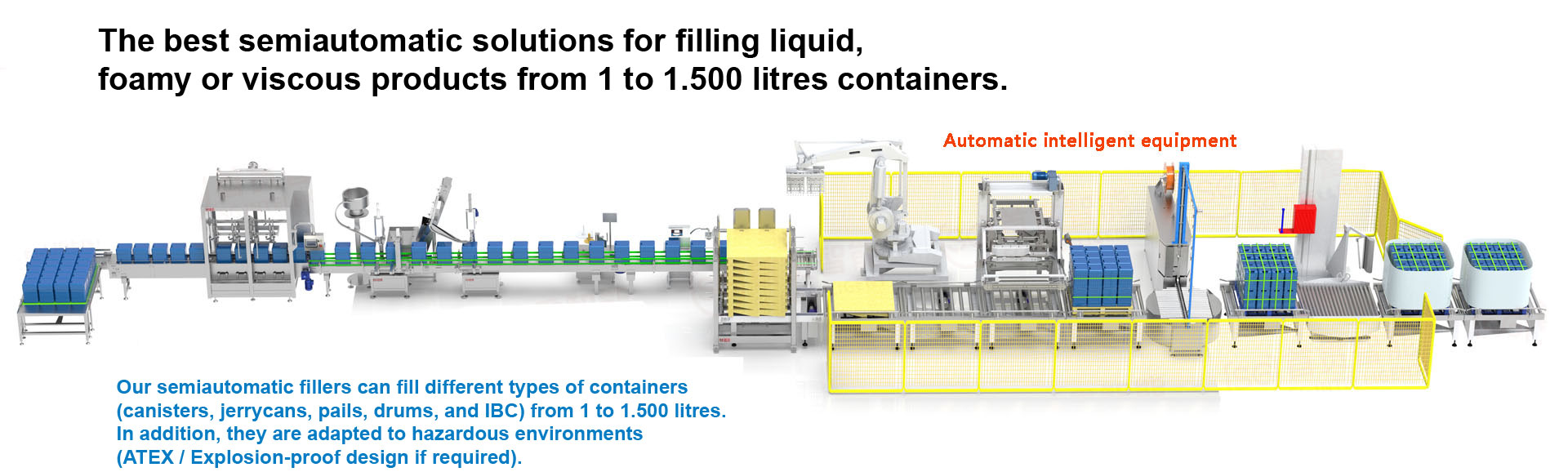

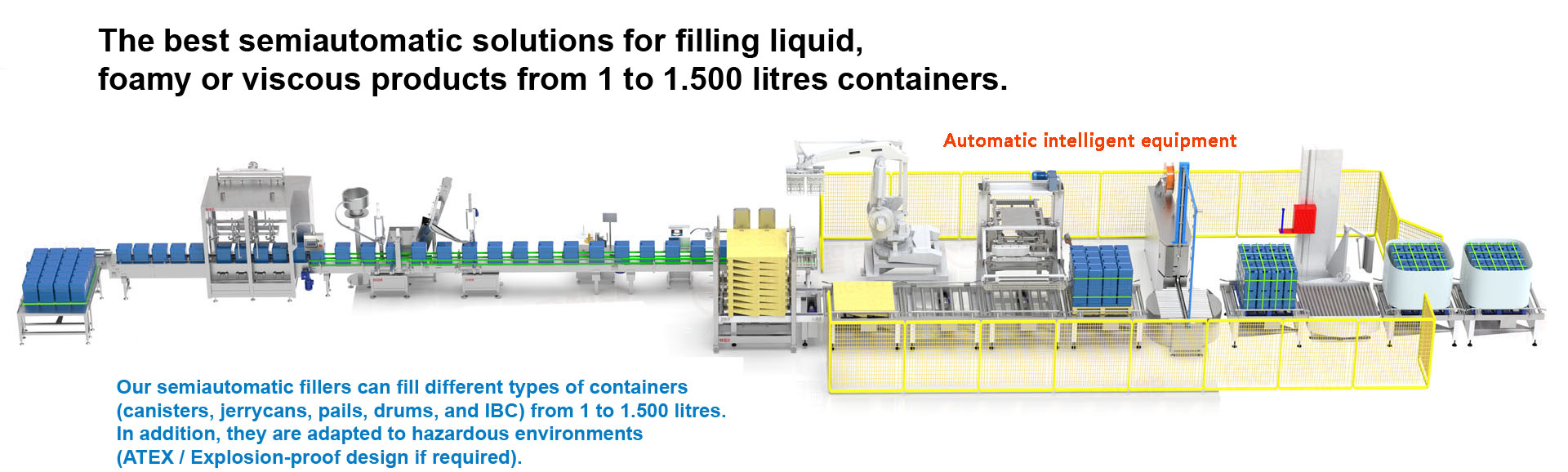

The semi-automatic drum filling machine is designed for efficient, precise, and safe filling of 200L drumse777乐彩线路检测 with liquid chemicals like latex paint. It combines manual operation with automated features to ensure accuracy, reduce labor, and minimize spills or contamination. Ideal for medium-to-high production volumes, this machine is suitable for industries such as paints, coatings, adhesives, and specialty chemicals.

Key Features

Semi-Automatic Operation

Manual Drum Placement: The operator positions the drum under the filling nozzle using a pallet jack or forklift.

Automated Filling Cycle:e777乐彩线路检测 Once initiated, the machine automatically fills the drum to the preset weight or volume.

Gravimetric Accuracy

High-Precision Load Cells:e777乐彩线路检测 ±0.1% to ±0.2% accuracy ensures consistent fill levels.

Real-Time Weight Tracking: Stops the flow instantly when the target weight is reached.

Chemical Compatibility

Corrosion-Resistant Materials: 316L stainless steel construction with optional PTFE or Hastelloy coatings for aggressive chemicals.

Latex Paint Specialization: Designed to handle viscous liquids like latex paint without clogging or degradation.

Safety & Compliance

ATEX/IECEx Certification:e777乐彩线路检测 Safe for hazardous environments (e.g., Zone 2/22).

Static Grounding System:e777乐彩线路检测 Prevents static sparks during filling.

Spill Containment: Drip trays and encapsulated hoses to manage leaks or splashes.

Nitrogen Blanketing (Optional): Inert gas purging to prevent foaming or oxidation.

Ease of Use

Touchscreen HMI:e777乐彩线路检测 Intuitive interface for setting batch weights, flow rates, and recipes.

Pre-Set Recipes: Store up to 100+ product profiles for quick selection.

Vacuum Purging: Minimizes product waste during nozzle purging cycles.

Customizable Options

Foam Management:e777乐彩线路检测 Anti-foam sensors and adjustable flow rates to prevent frothing.

Automated Lids/Caps (Optional): Integrated sealers for tamper-evident closures.

Ethernet Connectivity:e777乐彩线路检测 Remote monitoring and control via Wi-Fi or Ethernet.

Technical Specifications

Filling Range: 2–200 liters (adjustable for partial fills).

Accuracy: ±0.1% to ±0.2% of target weight.

Flow Rates: Adjustable from 10 L/min to 100 L/min (depending on viscosity).

Materials:e777乐彩线路检测 316L stainless steel, Hastelloy, or chemical-resistant polymers.

Power: 220V/50Hz or 110V/60Hz (energy-efficient motors).

Certifications: ATEX, IECEx, CE, ISO, NSF (for food/pharma applications).

Applications

Latex Paint: Water-based and oil-based paints.

Chemicals:e777乐彩线路检测 Acids, bases, solvents, adhesives, and specialty chemicals.

Coatings: Industrial coatings, varnishes, and enamels.

Food & Beverage: Edible oils, syrups, and bulk liquid ingredients.

Operation Steps

Position Drum: Place the 200L drum under the filling nozzle using a pallet jack or forklift.

Select Recipe:e777乐彩线路检测 Use the touchscreen to choose the product profile, target weight, and flow rate.

Start Filling:e777乐彩线路检测 Initiate the cycle manually; the machine begins automatic filling.

Automated Cutoff: The system stops filling once the target weight is reached.

Purge & Seal:e777乐彩线路检测 Vacuum purges residual product from the nozzle (optional sealing).

Unload Drum:e777乐彩线路检测 Remove the filled drum and apply a tamper-evident seal (optional).

Benefits

Precision: Gravimetric control ensures accurate fill weights, reducing overfilling or underfilling.

Efficiency: Faster cycle times compared to manual filling, with reduced labor costs.

Safety: ATEX certification, static grounding, and spill containment minimize risks.

Flexibility:e777乐彩线路检测 Compatible with a wide range of liquids and drum sizes.

Cost Efficiency: Reduces product waste, labor costs, and compliance risks.

Why Choose This Machine?

e777乐彩线路检测This semi-automatic drum filling machine is perfect for businesses requiring precision, safety, and efficiency in handling viscous liquids like latex paint. Its robust construction, user-friendly interface, and customizable features make it a reliable solution for medium-to-high production environments.

Contact us today for a customized solution tailored to your needs!

Immediate Order:

Website: http://fmnbp.org/product/drumfillingmachines-en.html

Alibaba:

China Manufacturing Co Ltd.:

-

Heavy-Duty Chemical Filling Machines - IBC, Drum & Tote Systems for Industrial Use[2025-05-21]

-

Gel Adhesive filling machine Reinforced Stainless Steel filling machine[2025-06-28]

-

10 L Multicolor Paint filling machine Scope of application[2025-06-28]

-

Chemical Liquid Automatic Filling Machine for Filling 5-25L Paint/Acrylic Acid/Pickling Agent[2025-07-05]