Heavy-Duty Chemical Filling Machines - IBC, Drum & Tote Systems for Industrial Use

Heavy-Duty Chemical Filling Machines: IBC, Drum & Tote Systems for Industrial Use

Overview

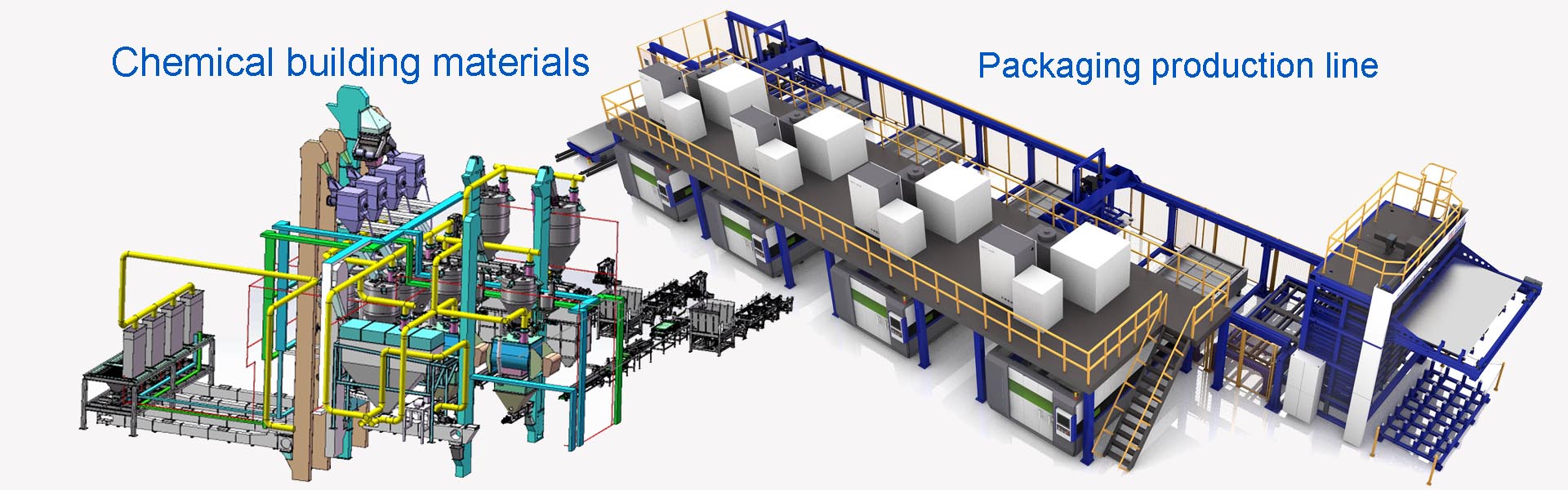

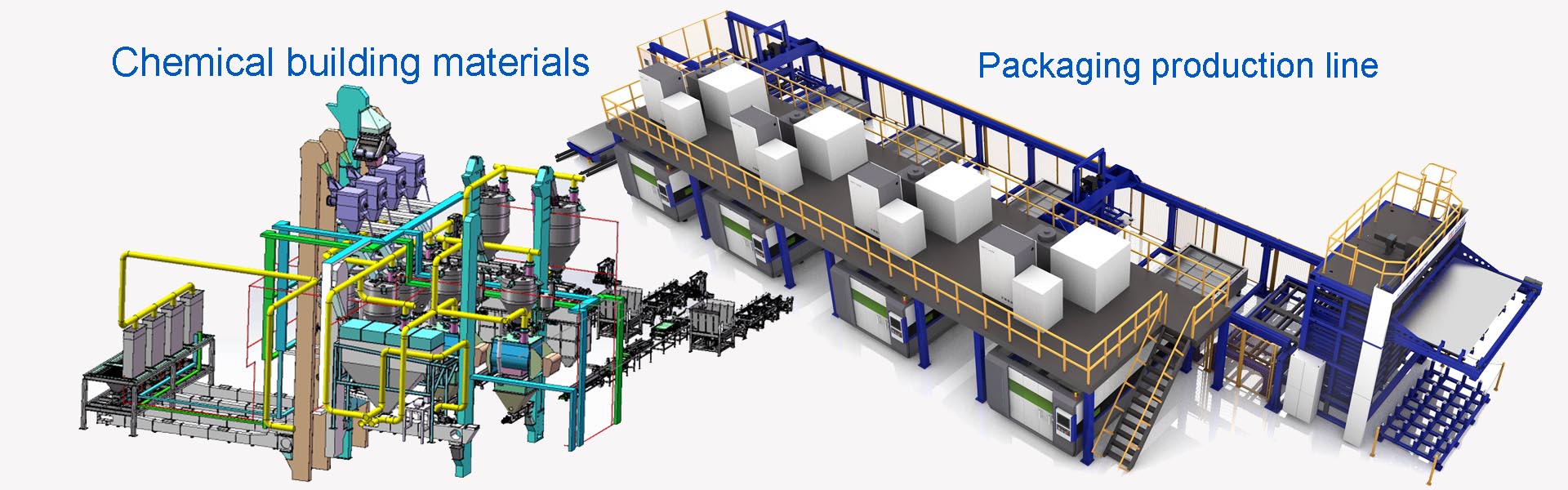

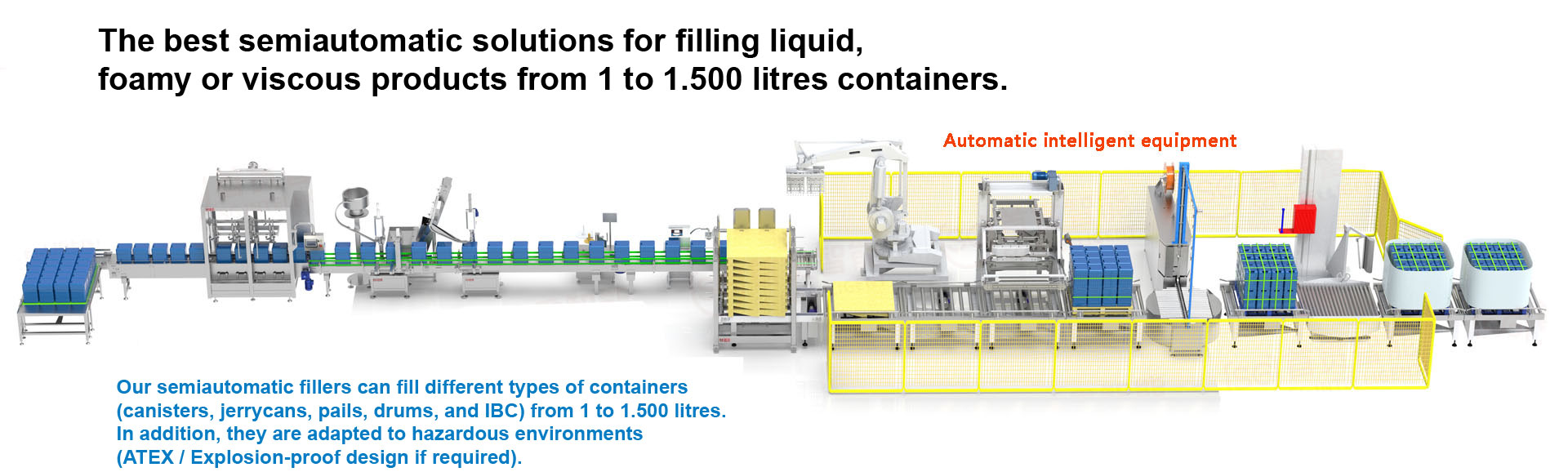

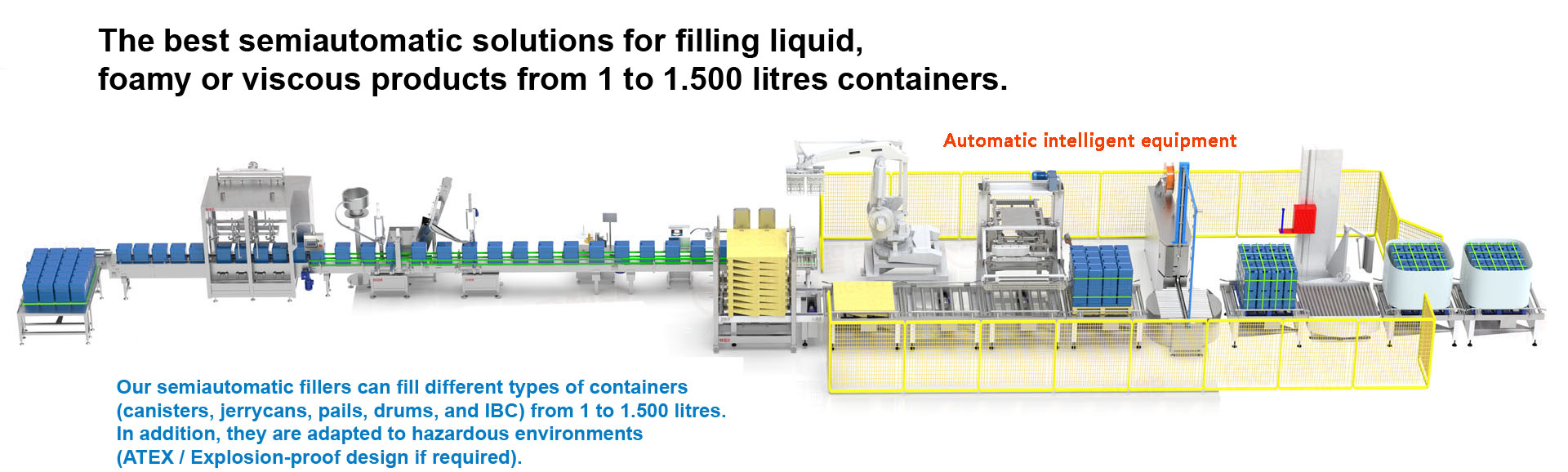

e777乐彩线路检测Designed for rigorous industrial environments, our heavy-duty chemical filling machines provide precise, reliable, and safe solutions for handling corrosive, hazardous, or high-viscosity chemicals. Compatible with IBCs (1,000L), drums (200L), and totes (1,000L), these systems ensure efficient workflows while prioritizing operator safety and environmental compliance.

Key Features

Robust Construction

Built with 316L stainless steel, Hastelloy, or PTFE coatings to resist corrosion from aggressive chemicals.

Explosion-proof (ATEX/IECEx) certification for safe use in volatile atmospheres.

e777乐彩线路检测Heavy-duty frames and wear-resistant components for longevity in demanding conditions.

Precision Filling

Accuracy of ±0.5% by weight or volume, with advanced load cells or flow meters.

e777乐彩线路检测Adjustable flow rates (1–120 L/min) to accommodate liquids, pastes, or viscous products.

Drip-free nozzles and splash-proof designs to minimize spills and cross-contamination.

Integrated Safety

e777乐彩线路检测Static dissipation systems and grounding protocols to eliminate spark risks.

Spill containment trays and catchment pans for leak protection.

e777乐彩线路检测Optional nitrogen blanketing or fume extraction arms to manage volatile fumes.

Automation & Control

Touchscreen HMI interface for recipe storage, real-time monitoring, and parameter adjustments.

e777乐彩线路检测PLC compatibility for seamless integration into automated production lines.

e777乐彩线路检测IoT-enabled remote diagnostics (optional) for predictive maintenance.

Versatility

Supports IBCs, drums, totes, and intermediate bulk containers with customizable nozzle options.

Inert gas purge capabilities to maintain product stability during filling.

e777乐彩线路检测Compliance with OSHA, EPA, and global hazardous material handling standards.

Applications

Chemicals: Acids, solvents, adhesives, and specialty formulations.

Petrochemicals:e777乐彩线路检测 Fuels, oils, biodiesel, and petrochemical blends.

Pharmaceuticals:e777乐彩线路检测 APIs, excipients, and liquid medications.

Food & Beverage:e777乐彩线路检测 Edible oils, syrups, and food-grade additives.

Industrial Lubricants:e777乐彩线路检测 Engine oils, greases, and heavy-duty lubricants.

Optional Enhancements

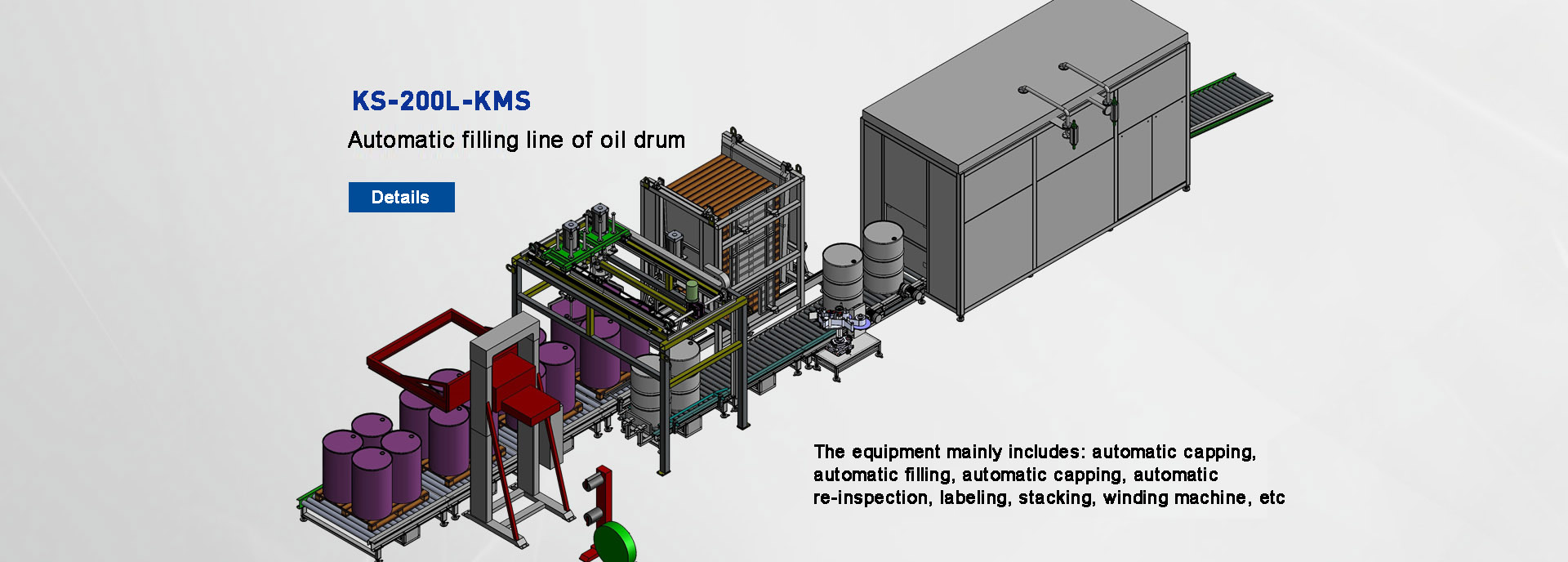

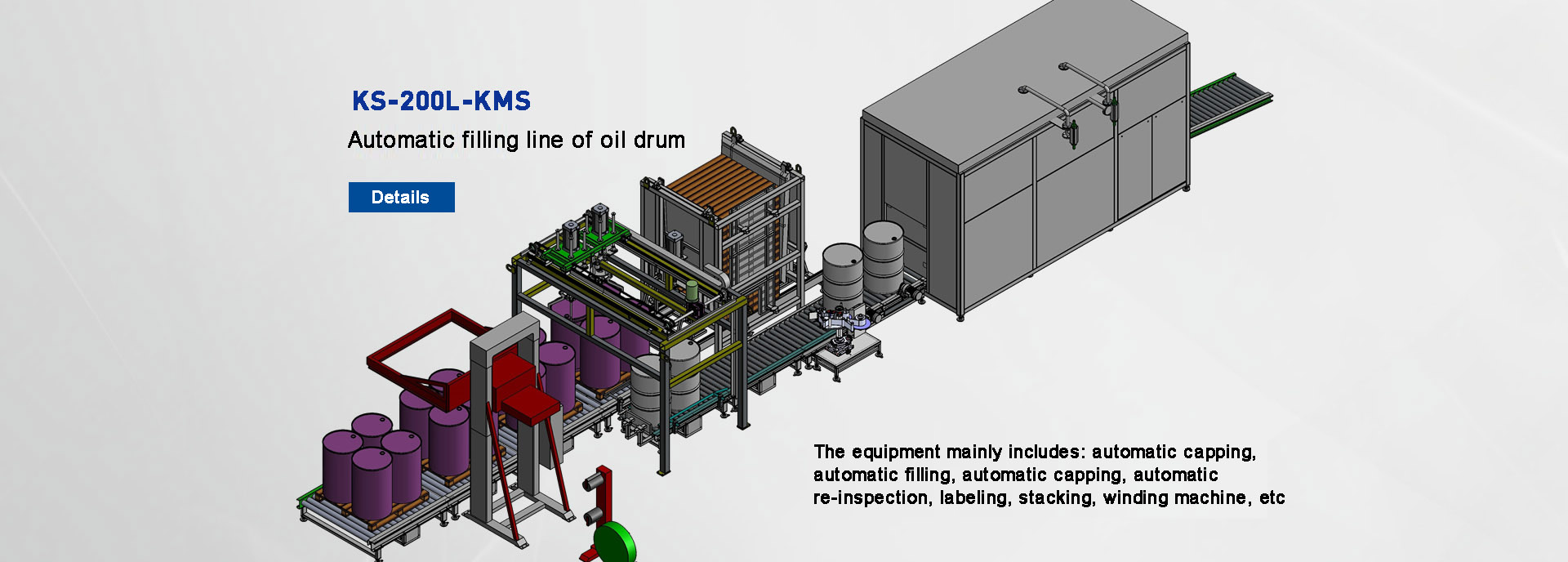

Conveyor systems for automated container loading/unloading.

e777乐彩线路检测Inline weighing scales for batch verification.

Barcode/batch labeling machines for traceability.

Vapor extraction arms for fume capture.

e777乐彩线路检测Automated capping modules for tamper-evident sealing.

Benefits

Durability:e777乐彩线路检测 Withstands harsh industrial conditions and corrosive chemistries.

Safety:e777乐彩线路检测 Explosion-proof design, static control, and spill prevention protect operations and personnel.

Flexibility:e777乐彩线路检测 Adaptable to diverse chemistries, container sizes, and automation requirements.

Compliance:e777乐彩线路检测 Ensures adherence to global safety and environmental regulations.

Scalability: Suitable for small-scale or large-scale industrial applications.

Why Choose These Systems?

Engineered for precision, safety, and reliability, these heavy-duty filling machines deliver consistent performance in the most challenging industrial settings. Whether handling corrosive acids, volatile solvents, or viscous oils, they offer a robust, customizable solution to streamline your filling processes while ensuring regulatory compliance and operator safety.

Contact Us to discuss your specific needs and explore customized configurations!

Immediate Order:

Website: http://fmnbp.org/product/drumfillingmachines-en.html

Alibaba:

e777乐彩线路检测China Manufacturing Co Ltd.:

-

Industrial 200L Drum Filling Machine for Chemicals and Engine Oil[2025-05-07]

-

Dual Workstation Fully Automatic filling machine Putty filling machine[2025-07-01]

-

Dual Gun Dual Measurement packaging machine Semi-Automatic Powder Form packaging machine[2025-07-01]

-

Semi Automatic 200L Pet Bottle Pure Water Filling Machine[2025-04-16]