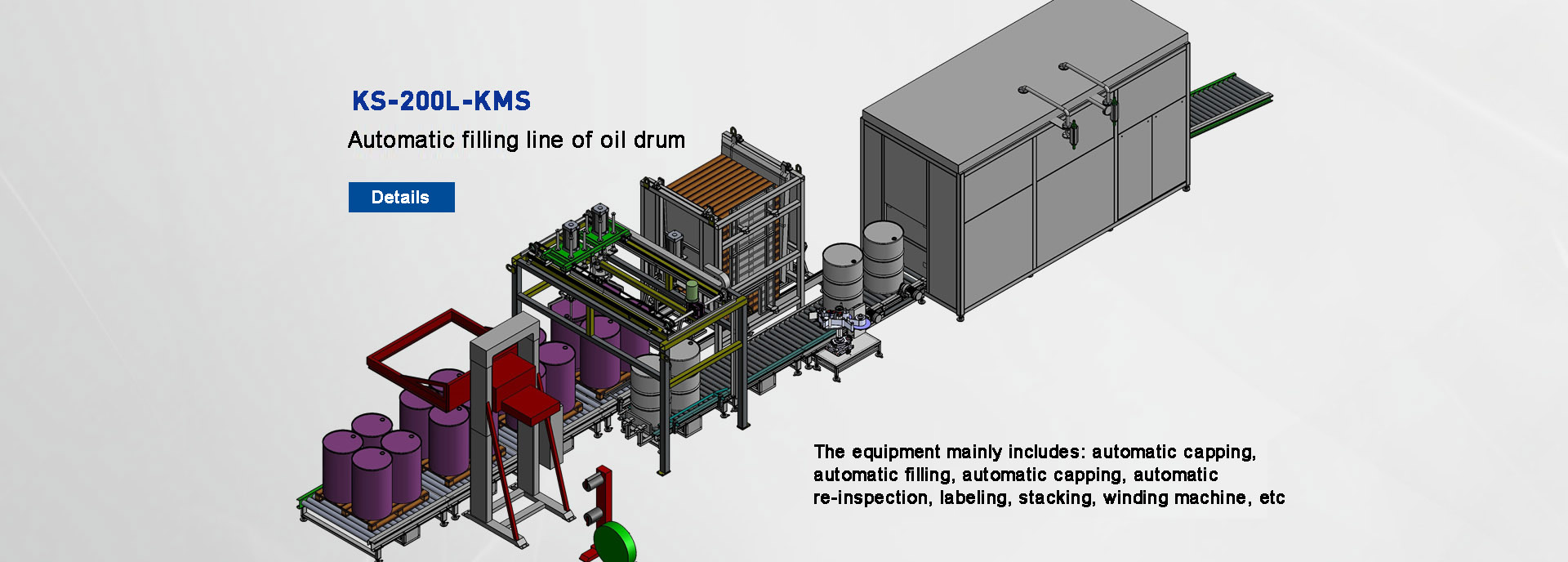

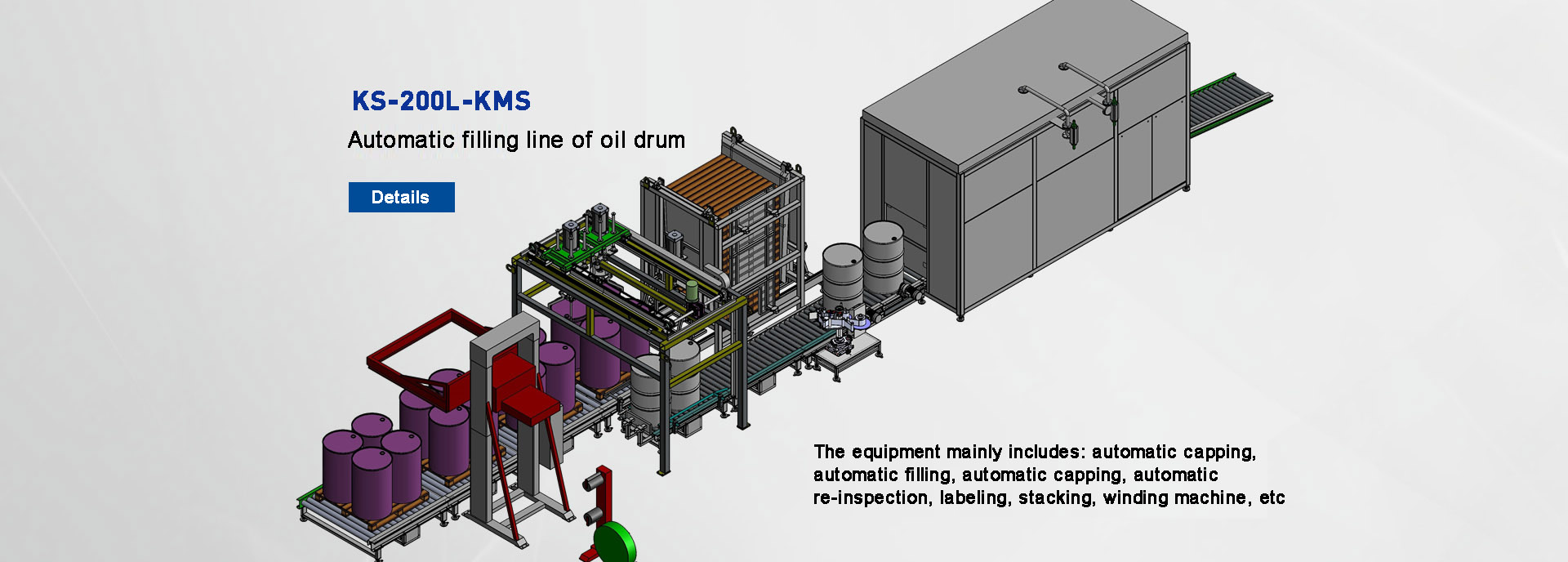

Product Introduction: Fully Automatic Drum Palletizer

Precision Stacking for Heavy-Duty Drum Handling

Shanghai Guangzhi Automation’s Drum Palletizer revolutionizes high-volume drum logistics with robotic intelligence and industrial-grade durability. Designed for 55-gallon (200L) drums, this system automates loading, stacking, and depalletizing at ±1mm accuracy and 80 drums/houre777乐彩线路检测 throughput. Integrating AI vision and servo-gripper technology, it eliminates manual handling risks while slashing labor costs by 70% – ideal for chemicals, food processing, and hazardous material warehouses.

Core Innovations

Adaptive Robotic Gripping

360° Adjustable Clamps: Auto-adjust to drum diameters (Ø400–650mm) and materials (steel/plastic/fiber).

Force-sensing technology prevents deformation (max. grip force: 2,500 kg).

AI 3D Vision Positioning

e777乐彩线路检测LiDAR scanners detect drum orientation/damage; correct stacking paths in real-time.

e777乐彩线路检测Compatible with mixed SKUs (e.g., hazardous/non-hazardous segregation).

Heavy-Duty Construction

Reinforced steel frame (load capacity: 3,000 kg/layer).

e777乐彩线路检测Corrosion-resistant coating (IP66 rating for washdown environments).

Smart Conveyor Integration

Powered roller conveyor with drum centering and height tracking (500–1,800 mm).

e777乐彩线路检测RFID pallet tracking ensures correct stacking sequence.

IoT Control Hub

Technical Specifications

| Parameter | Specification |

|---|

| Automation Level | Fully Autonomous |

| Drum Capacity | 55-gallon (200L) standard |

| Stacking Accuracy | ±1 mm |

| Throughput | 60–80 drums/hour |

| Max. Stack Height | 4 layers (customizable to 6) |

| Gripper Compatibility | Ø400–650mm drums; 80–300 kg/drum |

| Power Supply | 380V/50Hz, 7.5 kW + 0.8 MPa air |

| Cycle Time | 45–75 sec/drum |

| Dimensions (L×W×H) | 8,500 × 4,200 × 3,500 mm |

| Safety Compliance | CE, ISO 13849-1, ANSI/RIA R15.06 |

Industry Applications

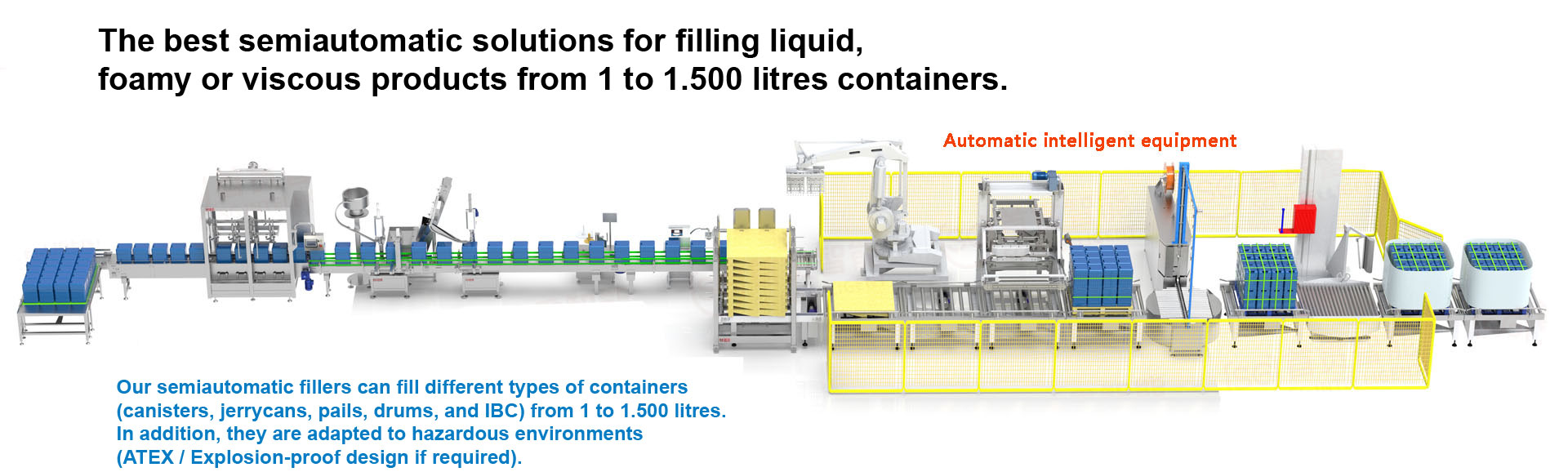

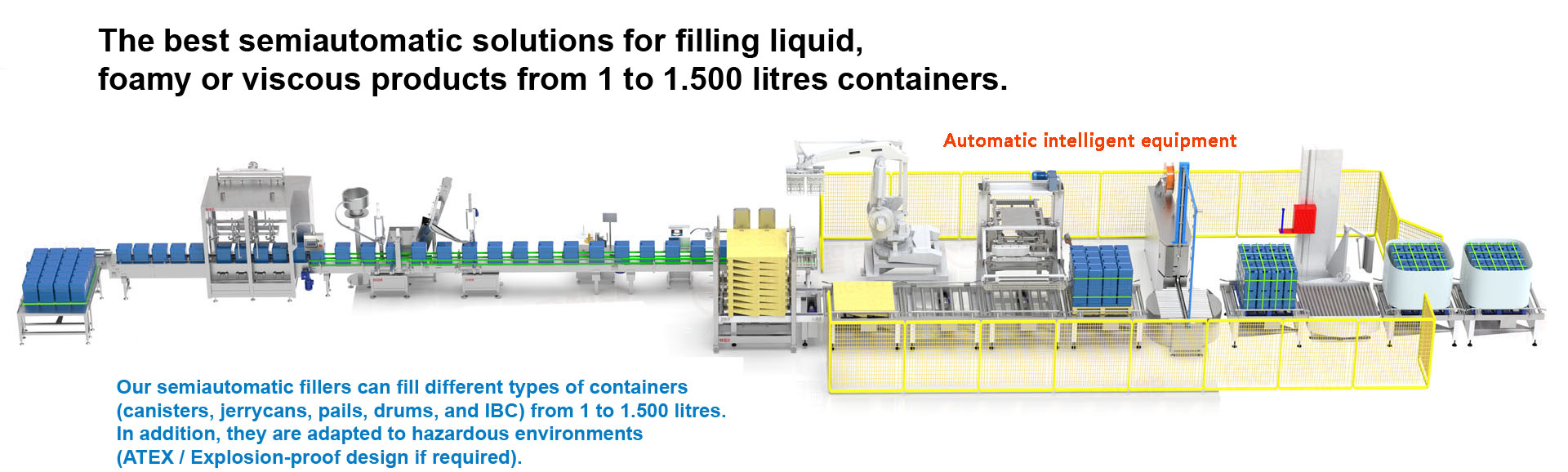

Chemical Plants: Stacking hazardous material drums (ATEX-certified version available).

Food & Beverage: Automated handling of edible oil/syrup drums (FDA-compliant materials).

Pharmaceuticalse777乐彩线路检测: GMP-compliant palletizing in sterile environments.

Waste Management: Handling recycled oil/lubricant containers.

Operational Advantages

Zero Manual Handling: Robotic arms replace 5+ laborers per shift.

99.9% Stack Stability: AI prevents toppling with optimized pyramid/brick patterns.

Rapid ROI: Payback in 8–14 months via labor/insurance cost reduction.

Future-Ready: Integrates with AGVs, WMS, and Guangzhi’s drum filling lines.

Spill Prevention: Leak sensors pause operation during drum damage detection.

Safety Systems