FIBC Bulk Bag Filling Solutions & Ton Bag Filler Manufacturer

Bagging (Manual):

Operator initiates the cycle by pressing the "bagging" button. The hydraulic lifting frame automatically lowers to the bagging position. The operator attaches the FIBC/sling straps to the four hooks and clamps the open mouth bag filling machine spout, creating a sealed connection. The lifting frame then rises automatically to the pre-set position.

Tare (Automatic):

The Bulk Bag Filling System automatically peels off the weight of the packaging bag (tare weight).

Fast-Feeding (Automatic):

The FIBC Ton Bag Filling Machine opens the feeding mechanism (gravity, belt, or screw spiral) for rapid filling. Simultaneously, the vacuum dust removal system activates. The weighing instrument continuously monitors material weight. Fast feeding stops when reaching the pre-set quick-feed weight value.

Slow Feeding (Automatic):

The Bulk Bag Filler seamlessly switches to precision slow feeding. Upon reaching the exact target weight (e.g., 500kg, 1000 Kg, 1 Ton, or 2 Ton), feeding stops. The feeder shuts off, and the material gate closes.

Unloading (Manual):

Post-filling, the pneumatic hooks retract, releasing the bag straps. The clamping device opens, freeing the spout. After a brief delay, the vacuum closes. The full Jumbo Bag falls onto a pallet. The operator starts the chain conveyor (via transport button) to move the palletized bag out for forklift removal.

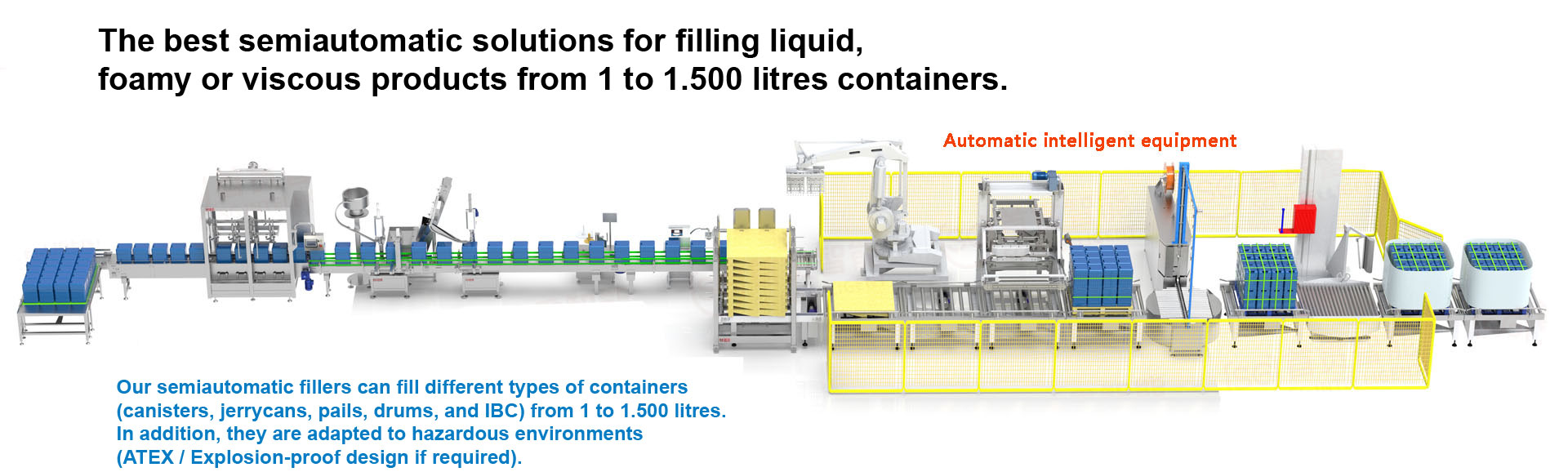

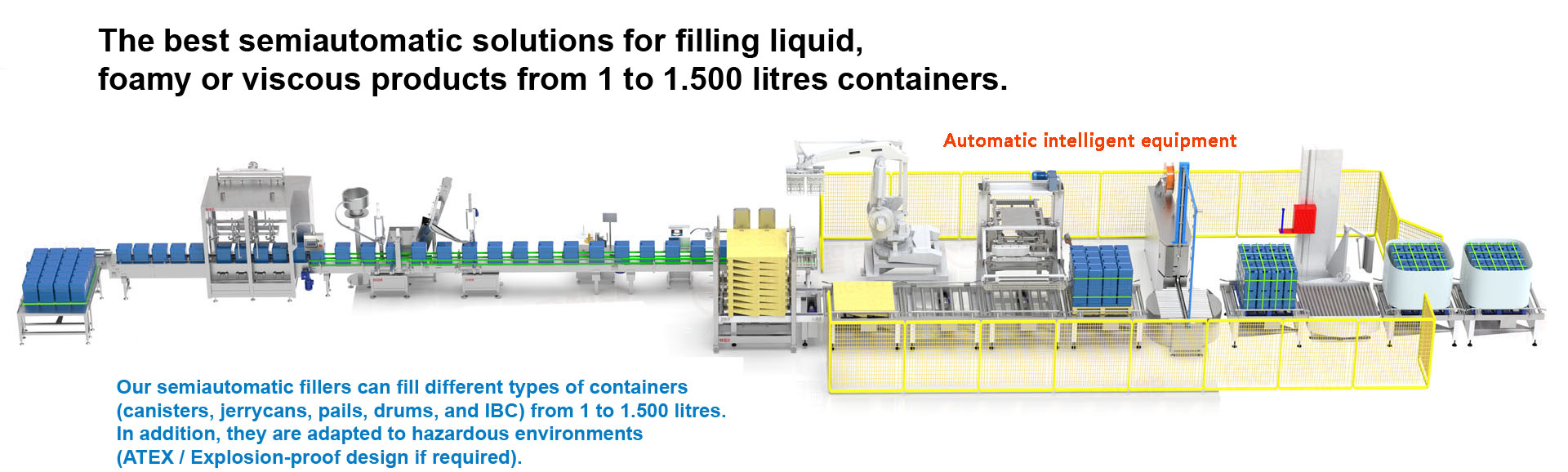

Ton Bag Packaging Machine Overview

The Ton Bag Packaging Machine (also known as Bulk Bag Filling Machine, FIBC Bag Filling System, or Big Bag Filler) is a large-scale, automated weighing and packaging solution designed for 1-2 Ton FIBC bag filling. This Bulk Bag Packing Machine integrates precise electronic weighing, automatic bag release, and dust removal. Key advantages include:

High Automation & Accuracy:

Dynamic weighing ensures ±0.5% precision.

Flexible Speed: Adjustable filling rates.

Robust Construction: Superior hydraulic lifting system simplifies handling 1000 Kg Big Bag or 2 Ton Bag operations, streamlining workflow.

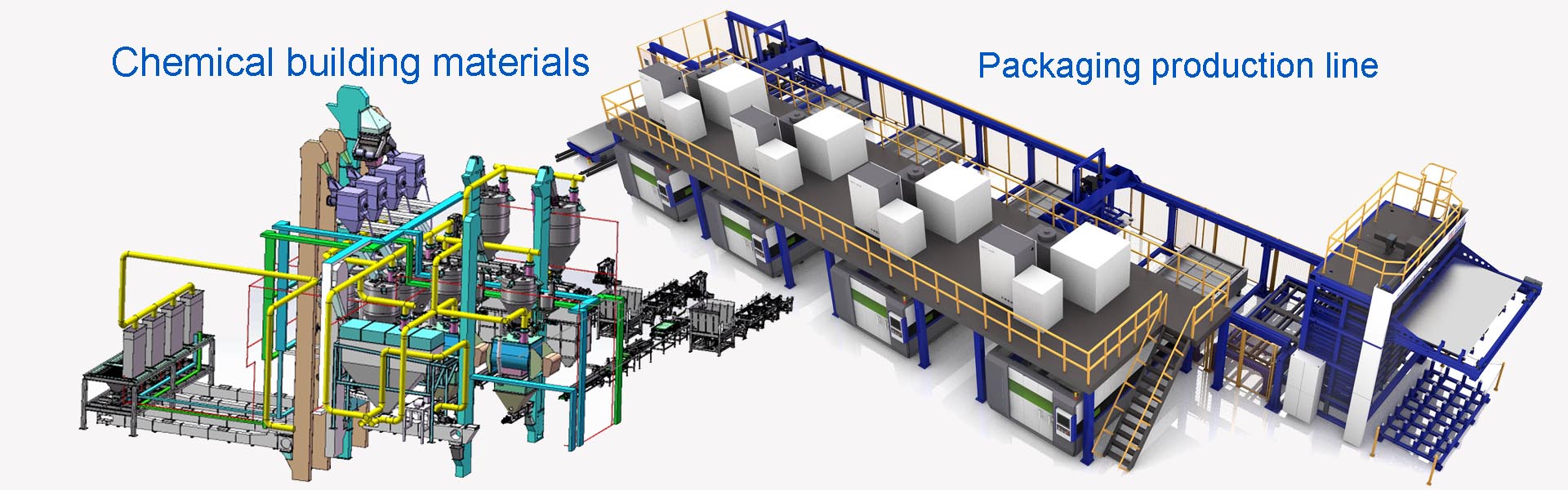

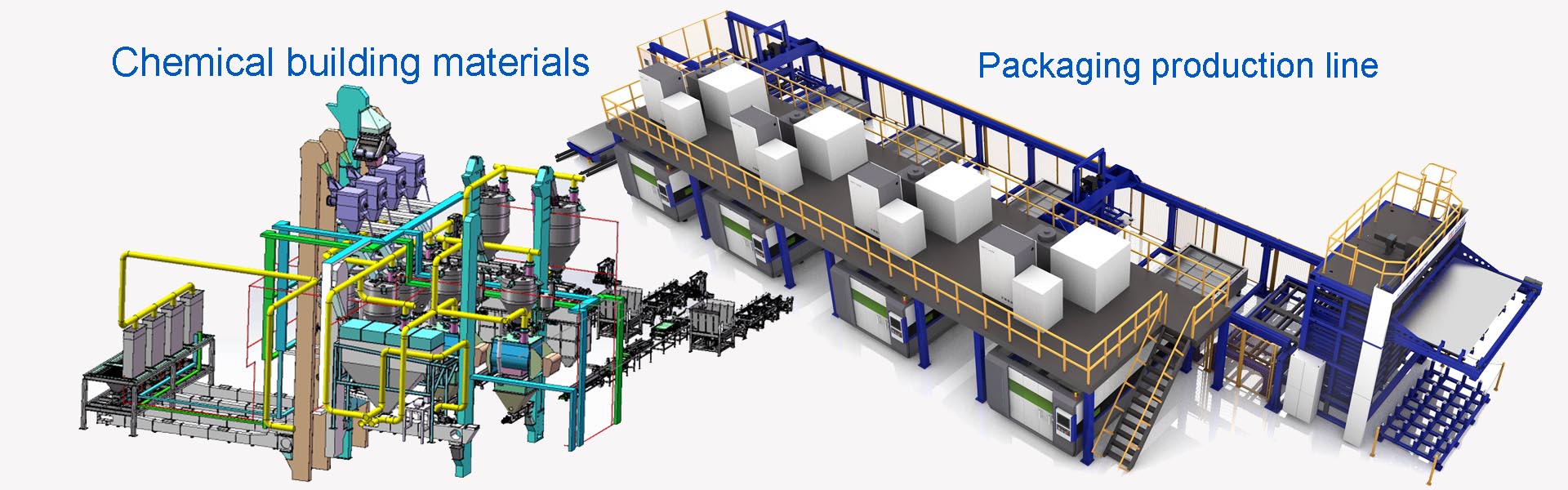

Versatile: Ideal for minerals, chemicals, building materials, grains, feed, and other bulk solids.

Main Structure of the FIBC Ton Bag Filling Machine

Pneumatic Hook & Bag Clamping System

Fast/Slow Feeding Mechanism (Gravity, Belt, Screw Spiral)

Precision Weighing Device

Hydraulic Lifting Frame

Conveyor Raceway

Electrical Control System

Technical Parameters

Weighing Range: 500kg - 2 Ton/Bag

Capacity: 2-3 Bags/Hour

Accuracy: ±0.5% (Dynamic)

Power: 380V, 50Hz

Design: Optimized for Open Mouth Bag Filling Machine operation.

Looking for a reliable Bulk Bag Filler Manufacturer? Explore competitive Ton bag filling machine price options and find the ideal Ton bag filling machine for sale to meet your high-capacity Big Bag Filling Packing Machine requirements. This Bulk Bag Filling System offers unmatched efficiency for FIBC Big Bag Filling Machine applications.