25L About Semi-automatic Hopper Ex-Proof Pail Filling Machine for Washing Coatings/Wine Chemicals

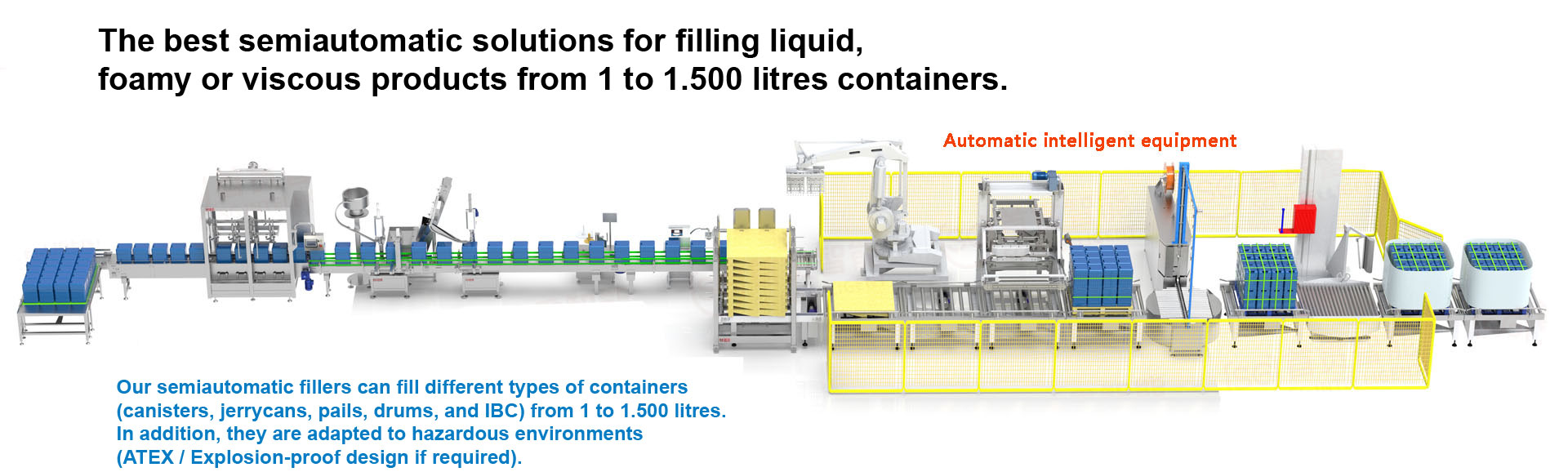

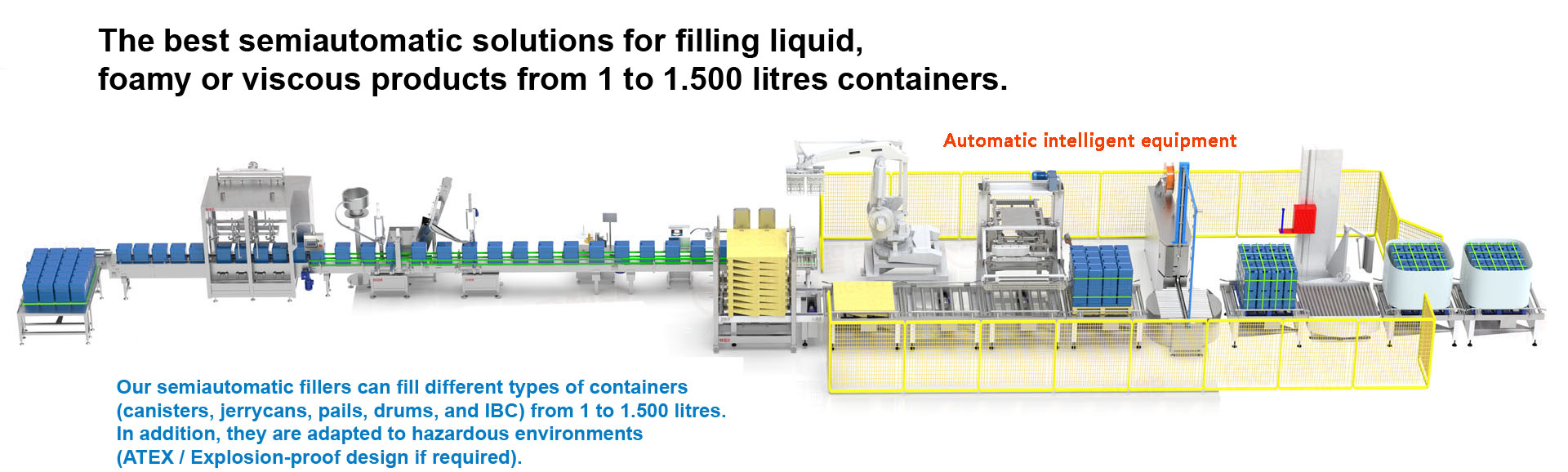

The 25L Semi-Automatic Hopper Ex-Proof Pail Filling Machine is a specialized piece of equipment designed for safely and accurately filling 25-liter pails with hazardous or flammable materials, such as washing coatings, wine chemicals, or other industrial liquids. The "Ex-Proof" (or explosion-proof) design ensures compliance with safety standards in environments where volatile substances are present. Below is a detailed overview of its features, benefits, applications, and key considerations.

Key Features:

Ex-Proof Design:

Complies with international safety standards (e.g., ATEX, IECEx, NEC) for use in explosive atmospheres.

e777乐彩线路检测Made from anti-static and flame-resistant materials to prevent sparks or ignition.

Suitable for environments with flammable liquids or gases.

25L Capacity:

Specifically designed for filling 25-liter pails, a common size for industrial liquids.

Adjustable fill volumes to accommodate different product requirements.

Semi-Automatic Operation:

Operator-controlled filling process for flexibility and precision.

Manual loading of pails and initiation of the filling cycle.

Stainless Steel Construction:

e777乐彩线路检测Made from high-grade stainless steel (304/316) for corrosion resistance and compatibility with aggressive chemicals.

Easy to clean and maintain, ensuring hygiene and longevity.

Precision Filling System:

High-accuracy flow meters or load cells ensure precise filling within ±0.1% to ±0.5% of the target weight.

Adjustable filling speeds to prevent splashing or foaming.

Drip-Free Filling Nozzle:

Designed to minimize product wastage and spillage during filling.

e777乐彩线路检测Self-closing or automatic shutoff after filling is complete.

Static Grounding System:

e777乐彩线路检测Integrated static grounding to safely discharge any static electricity and reduce the risk of ignition.

Safety Interlocks:

e777乐彩线路检测Equipped with safety interlocks to prevent accidental operation when the hopper or filling nozzle is not properly positioned.

e777乐彩线路检测Emergency stop buttons for operator safety.

Hopper with Agitation:

A stirred hopper to keep the product uniformly mixed and prevent settling of solids.

Option for heating or cooling the hopper if required for temperature-sensitive products.

Customizable Options:

e777乐彩线路检测Optional data logging for tracking batch weights, production counts, and operator activity.

e777乐彩线路检测Integration with larger automation systems (e.g., PLC, SCADA) for seamless workflow.

Benefits:

Safety:e777乐彩线路检测 Ex-proof design and static grounding ensure safe operation in hazardous environments.

Accuracy: Precision filling minimizes overfilling or underfilling, reducing product waste and costs.

Versatility:e777乐彩线路检测 Suitable for a wide range of liquids, including flammable, corrosive, or viscous materials.

Ease of Use: Semi-automatic operation reduces labor intensity while maintaining control over the filling process.

Durability:e777乐彩线路检测 Stainless steel construction withstands harsh industrial environments and chemical exposure.

Compliance: Meets international safety standards for explosive atmospheres, ensuring regulatory compliance.

Applications:

Washing Coatings:e777乐彩线路检测 Filling pails with flammable or solvent-based cleaning chemicals.

Wine Chemicals: Packaging additives, preservatives, or processing chemicals used in winemaking.

Industrial Chemicals: Filling pails with acids, bases, solvents, or other hazardous liquids.

Paints and Coatings: Packaging flammable or solvent-based paints and coatings.

Oil and Gas:e777乐彩线路检测 Filling pails with drilling fluids, lubricants, or other petroleum-based products.

Pharmaceuticals: Packaging flammable or volatile pharmaceutical ingredients.

Food and Beverage:e777乐彩线路检测 Filling pails with edible oils, flavorings, or other food-grade liquids.

Operation Steps:

Pail Loading:

e777乐彩线路检测The operator places an empty 25L pail under the filling nozzle.

Filling Process:

The operator initiates the filling cycle, and the machine dispenses the liquid into the pail.

e777乐彩线路检测The precision filling system ensures accurate volume control.

Dripping and Sealing:

The nozzle automatically shuts off or closes to prevent dripping after filling is complete.

Pail Removal:

e777乐彩线路检测The filled pail is removed and sealed if required.

Cleaning and Maintenance:

The machine is cleaned between batches to prevent cross-contamination.

e777乐彩线路检测Routine maintenance ensures optimal performance and safety.

Why Choose This Machine?

The 25L Semi-Automatic Hopper Ex-Proof Pail Filling Machinee777乐彩线路检测 offers a safe, accurate, and reliable solution for filling hazardous or flammable liquids into 25L pails. Its ex-proof design, precision filling, and durable construction make it ideal for industries handling dangerous materials. Whether you’re in the chemical, pharmaceutical, or food sectors, this machine provides a cost-effective way to meet your packaging needs while ensuring operator safety and regulatory compliance.

For customization or technical assistance, consult with suppliers like GLZON or other reputable manufacturers to ensure the machine meets your specific requirements.

Immediate Order:

Website: http://fmnbp.org/product/drumfillingmachines-en.html

Alibaba:

e777乐彩线路检测China Manufacturing Co Ltd.:

-

Auto Drum and IBC Filling Machine for Filling Color Paste Inks/Lubricants[2025-03-31]

-

200 L Fully Automatic Immersion Type filling machine Intelligent equipment[2025-07-02]

-

Semi-Automatic Jam/Salad Dressing/Peanut Butter/Paint Cans Filling Machine for 5-30L[2025-05-30]

-

Multi-Pails Automatic Liquid Filling Machine Is Suitable for Filling Vegetable Oil/Lubricating Oil/Solvent[2025-04-07]