150kg LPG Gas Cylinder Can Filling Machine

150kg LPG Gas Cylinder Can Filling Machine

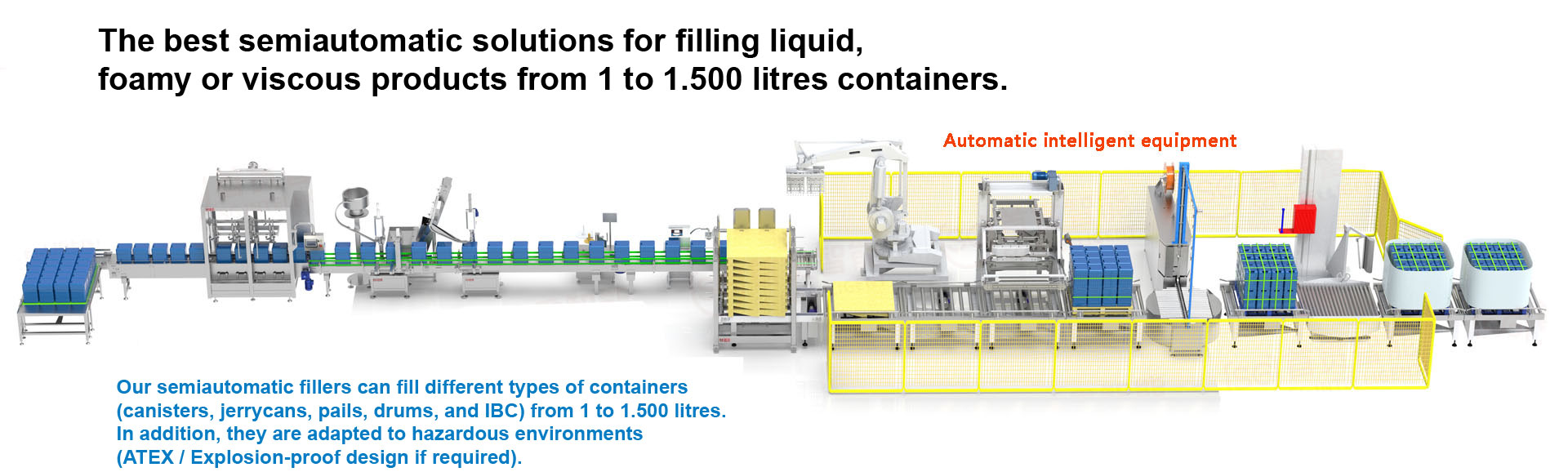

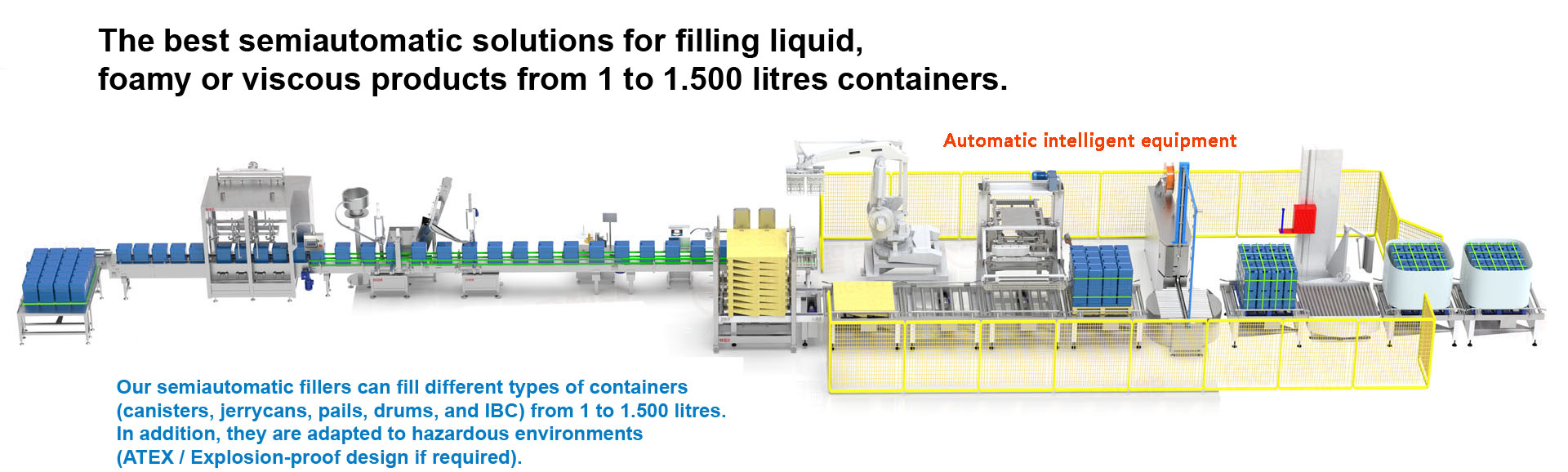

A 150kg LPG Gas Cylinder Can Filling Machine is a specialized system designed for the precise, safe, and efficient filling of 150kg LPG (Liquefied Petroleum Gas) cylinders. This machine integrates advanced weighing technology, automated controls, and safety features to ensure accurate filling, regulatory compliance, and operator safety. Below is a detailed overview of its key components, benefits, and applications.

Key Features:

High-Precision Weighing System:

Load Cellse777乐彩线路检测: Capable of accurately measuring up to 150kg or more, ensuring precise fill levels.

Digital Weighing Terminale777乐彩线路检测: Displays real-time weight data and allows for preset target weights.

Automatic Cutoff: Stops filling once the target weight is reached, preventing overfilling.

Automated Filling Process:

PLC Controle777乐彩线路检测: Manages the entire filling process, ensuring consistency and accuracy.

Servo/Pneumatic Valves: Controls the flow of LPG into the cylinder, allowing for adjustable filling speeds.

Filling Nozzle: Designed for safe and efficient transfer of LPG into the cylinder.

Safety Features:

ATEX/IECEx Certification: Suitable for use in hazardous environments (explosive atmospheres).

Pressure Relief Valvese777乐彩线路检测: Prevents overpressurization of cylinders during filling.

Emergency Stop: Instant shutdown in case of emergencies.

Leak Detection: Sensors detect and alert operators to any gas leaks during the filling process.

Temperature and Pressure Control:

Thermostatic Control: Maintains optimal temperature during filling to prevent flash vaporization or condensation.

Pressure Regulation: Ensures consistent pressure during filling to avoid cylinder rupture or incomplete fills.

Data Logging and Traceability:

HMI (Human-Machine Interface)e777乐彩线路检测: Touchscreen interface for easy operation and monitoring.

Batch Identification: Records fill weights, times, and batch numbers for traceability.

USB/Ethernet Ports: Exports data for compliance with regulatory requirements.

Customization and Flexibility:

Adjustable Filling Speedse777乐彩线路检测: Variable speed control to accommodate different cylinder sizes and LPG viscosities.

Multi-Cylinder Supporte777乐彩线路检测: Can handle various cylinder sizes (e.g., 50kg, 100kg, 150kg) with quick changeovers.

Gas Composition Compatibility: Suitable for filling propane, butane, or mixed LPG gases.

Environmental Protection:

Vapor Recovery Systeme777乐彩线路检测: Minimizes emissions by capturing and reusing LPG vapors during filling.

Drip Trays: Collects any liquid spills, preventing environmental contamination.

Integration Capabilities:

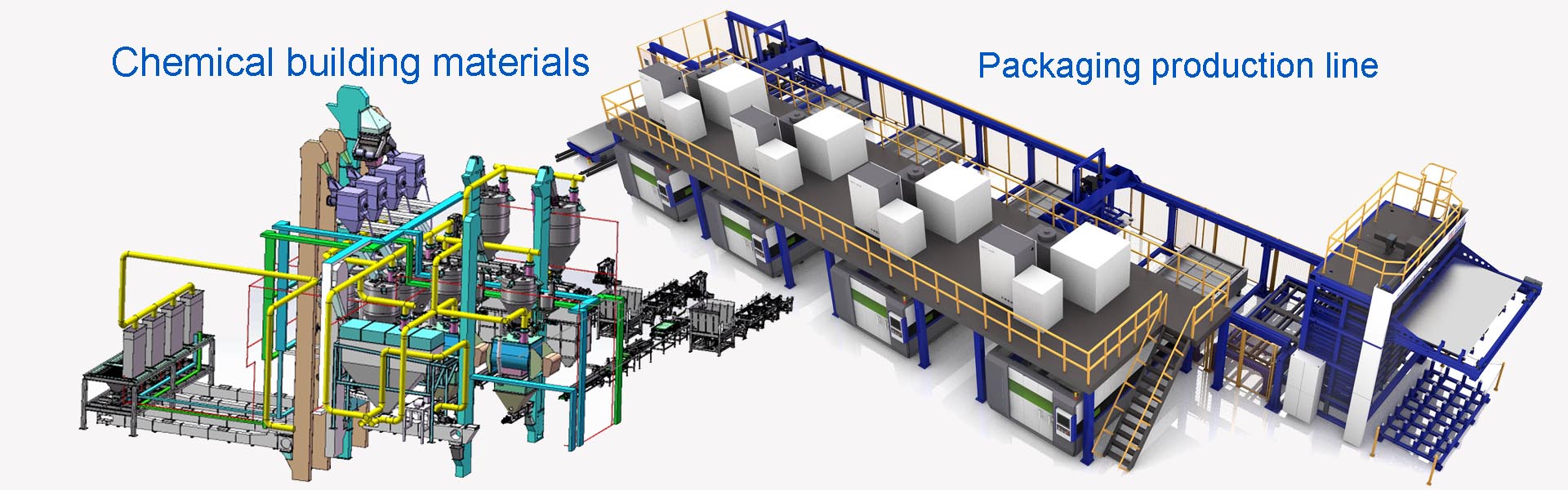

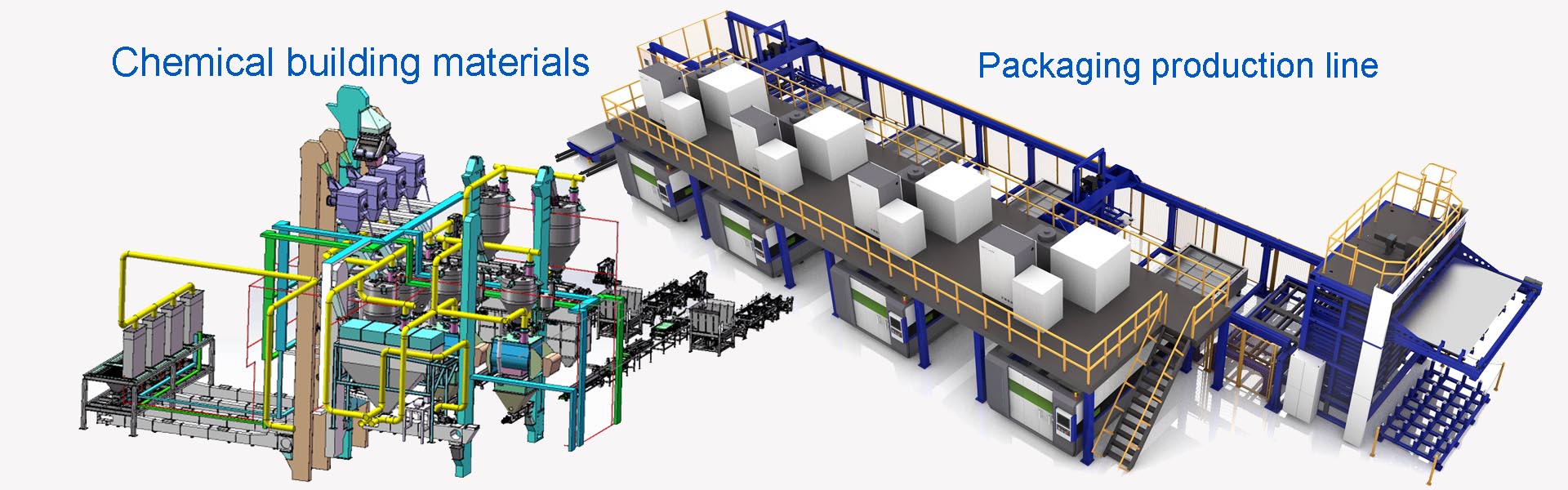

Upstream Integratione777乐彩线路检测: Connects with storage tanks, pumps, and mixing systems.

Downstream Integration: Compatible with labeling machines, capping systems, and palletizers for a fully automated workflow.

Benefits:

Accuracy and Consistency:

e777乐彩线路检测High-precision weighing ensures each cylinder is filled to the exact target weight, reducing waste and ensuring product quality.

Safety:

Advanced safety features (e.g., ATEX certification, leak detection, emergency stop) protect operators and prevent accidents.

Efficiency:

Automated filling reduces labor costs and increases throughput, making it ideal for high-volume operations.

Compliance:

Data logging and traceability ensure adherence to regulatory requirements (e.g., OSHA, EPA, and local safety standards).

Cost Savings:

Minimizes product loss, reduces labor costs, and lowers maintenance expenses due to robust design and automation.

Scalability:

Suitable for small, medium, or large-scale operations, with options for semi-automatic or fully automatic configurations.

Applications:

LPG Distribution:

Filling 150kg LPG cylinders for residential, commercial, or industrial use.

Petroleum Refineries:

Bottling LPG for distribution to retailers or bulk consumers.

Gas Stations:

Filling cylinders for sale to consumers or for use in portable stoves and heaters.

Industrial Use:

Filling cylinders for use in manufacturing processes, such as metal cutting or heating applications.

Export and Transport:

e777乐彩线路检测Preparing cylinders for export or transport to other facilities.

Why Choose This Machine?

Unmatched Accuracy: High-precision weighing and automated cutoff ensure each cylinder is filled to the exact target weight.

Fully Automated Workflow: Minimizes labor costs and increases productivity by handling cylinder loading, filling, and unloading.

Safety and Compliancee777乐彩线路检测: ATEX/IECEx certification and advanced safety features ensure safe operation in hazardous environments.

Customizatione777乐彩线路检测: Tailored to meet specific industry requirements, such as vapor recovery, pressure control, or multi-cylinder support.

Scalabilitye777乐彩线路检测: Suitable for small-scale or large-scale operations, with options for integration into broader production lines.

Invest in a 150kg LPG Gas Cylinder Can Filling Machine to streamline your operations, ensure product quality, and enhance safety. This system combines precision, efficiency, and scalability to meet the demands of modern LPG distribution and packaging industries.

Immediate Order:

Website: http://fmnbp.org/product/drumfillingmachines-en.html

Alibaba:

China Manufacturing Co Ltd.: