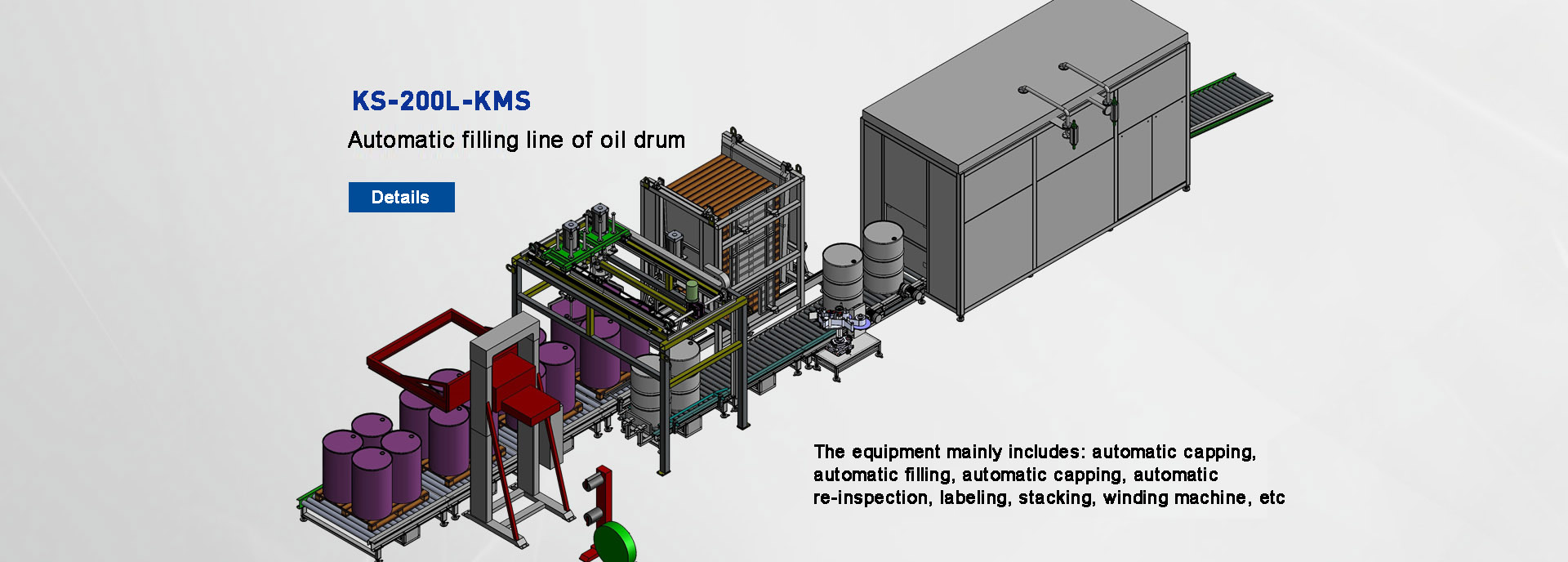

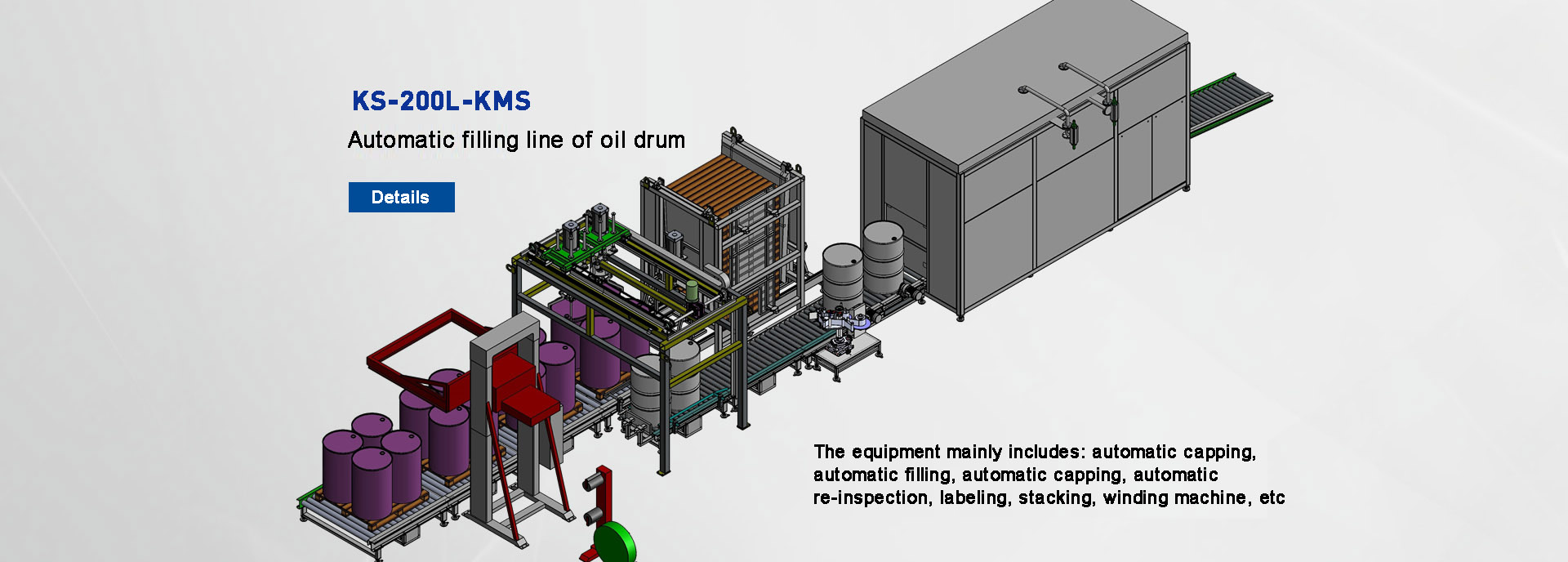

Industrial Bulk Filling System - IBC, Drum & Tote Filling Equipment

Industrial Bulk Filling System | IBC, Drum & Tote Filling Equipment

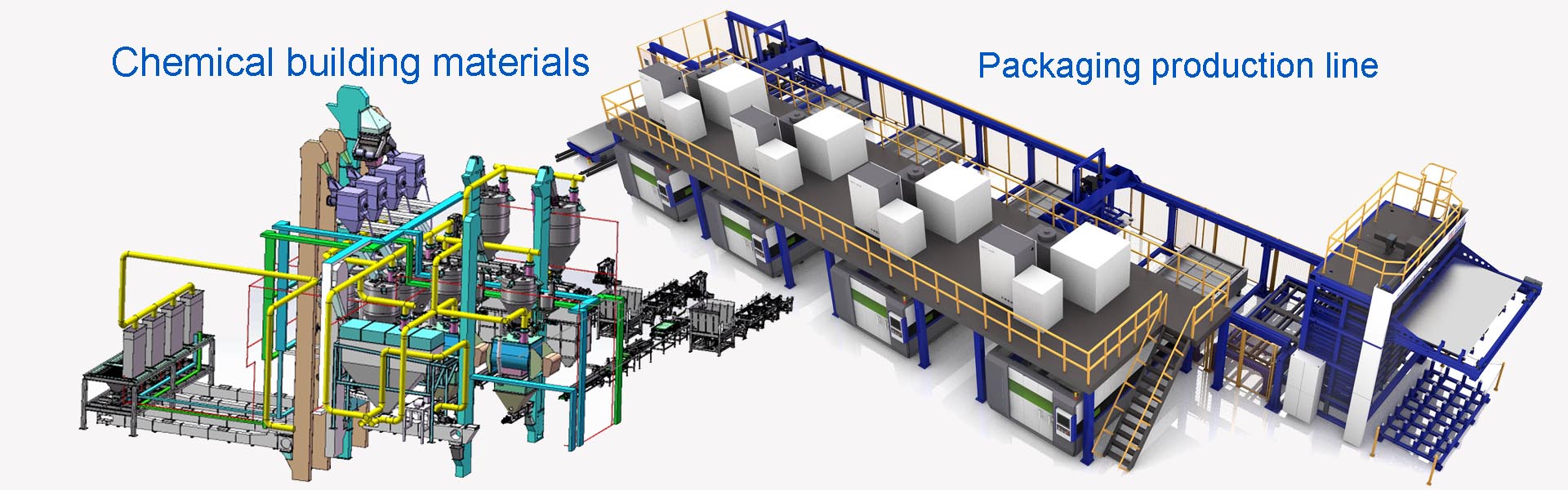

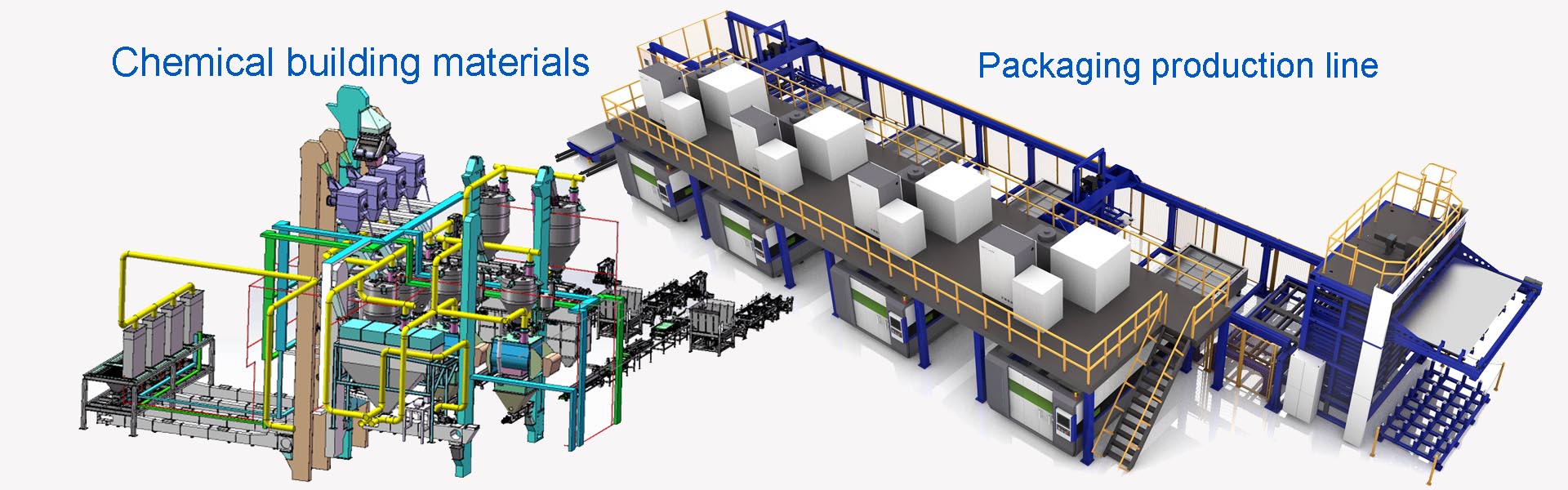

Machine Overview

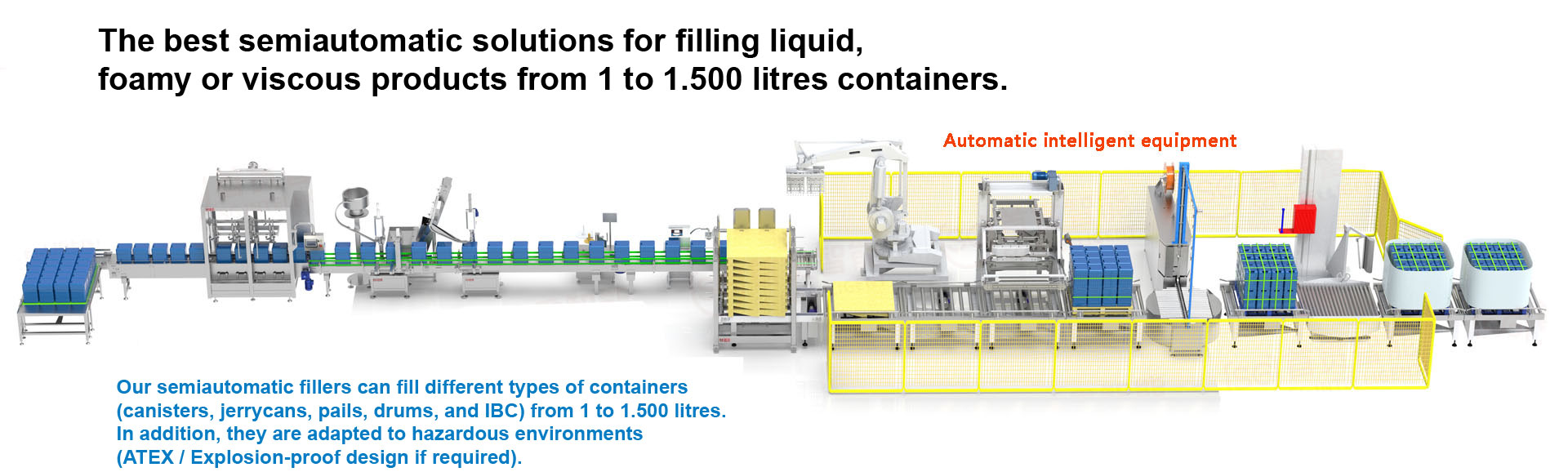

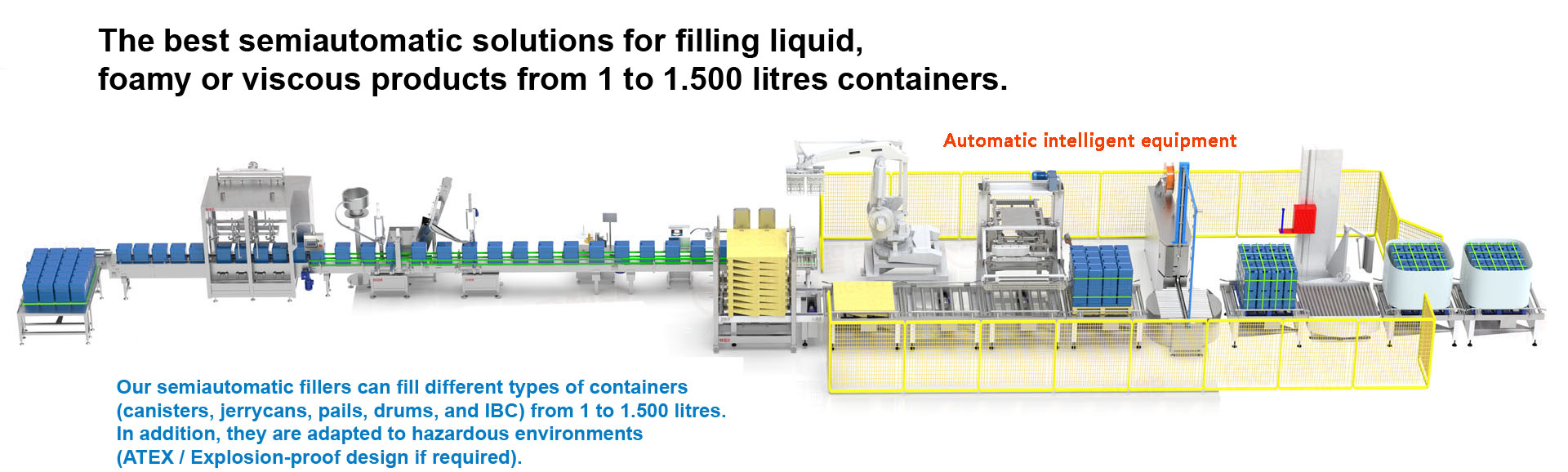

The industrial bulk filling systeme777乐彩线路检测 is a robust, automated solution designed for efficient and precise filling of intermediate bulk containers (IBCs), drums, totes, and other industrial vessels. It combines advanced technology, versatility, and safety features to meet the demands of industries such as chemicals, food and beverage, pharmaceuticals, oil, and agriculture.

Key Features

Precision Filling

Accurate Metering: Equipped with flow meters and level sensors to ensure exact fill volumes, minimizing product waste and maintaining consistency.

Adjustable Speed: Customizable filling rates to match production requirements.

Versatility

Container Compatibility: Suitable for IBCs, drums, totes, and other containers of varying sizes and materials.

Liquid Handling: Capable of filling a wide range of liquids, including hazardous, corrosive, viscous, and high-purity products.

Safety and Compliance

Spill Prevention: Integrated spill containment systems and automatic shut-off mechanisms to prevent leaks.

ATEX/IECEx Certification: Safe for use in hazardous environments (optional for explosive atmospheres).

Static Grounding: Ensures safe handling of flammable products.

Durability and Low Maintenance

Stainless Steel Construction: Corrosion-resistant materials for longevity and hygiene.

Easy Cleaning: Smooth surfaces and accessible components for quick sanitization.

User-Friendly Operation

Touchscreen Interface: Intuitive controls for easy setup, operation, and recipe management.

Pre-Programmed Recipes: Store settings for different products, container sizes, and fill volumes.

Automation and Integration

Conveyor Systems: Seamless integration with conveyors for automated container handling.

Data Logging:e777乐彩线路检测 Track fill volumes, batch numbers, and other critical data for traceability.

Applications

Chemicals: Filling corrosive or hazardous liquids.

Food & Beverage:e777乐彩线路检测 Aseptic filling of edible oils, sauces, and beverages.

Pharmaceuticals: Precision filling of syrups, solvents, and active ingredients.

Oil & Lubricants: High-viscosity liquid filling.

Agriculture: Fertilizers, pesticides, and other agrochemicals.

Benefits

Increased Efficiency:e777乐彩线路检测 Faster filling cycles and reduced labor costs.

Improved Safety: Minimizes operator exposure to hazardous materials.

Consistent Quality: Accurate filling ensures product integrity.

Scalability:e777乐彩线路检测 Modular design allows for future upgrades and expansion.

Customization Options

Material Options: Stainless steel, carbon steel, or custom coatings.

Automation Levels:e777乐彩线路检测 From semi-automatic to fully automated systems.

Special Features:e777乐彩线路检测 Nitrogen blanketing, vacuum filling, or heating/cooling jackets.

Why Choose This System?

Proven Reliability:e777乐彩线路检测 Trusted by global industry leaders.

Global Support: Worldwide shipping, installation, and after-sales service.

Competitive Pricing: High-quality equipment at affordable prices.

Get Started Today!

For a customized solution tailored to your specific needs, consult with our team. We provide consultation, installation, training, and ongoing support to ensure your success.

(Note: Contact details and company-specific information can be provided upon request.)

This description focuses on the machine’s capabilities, features, and benefits without mentioning company names or contact details.

Immediate Order:

Website: http://fmnbp.org/product/drumfillingmachines-en.html

Alibaba:

China Manufacturing Co Ltd.:

-

Efficient Equal Level Filling System for 10-30L Containers[2025-07-05]

-

Fully Automatic Tray Filling Machine for Filling 200L Plant Nutrient Solution[2025-07-05]

-

200L fully automatic filling machines[2025-02-17]

-

30L Paint and Coating Filling Machine Liquid Surface Filling Machine-filling Stable and Fast-stable[2025-05-08]