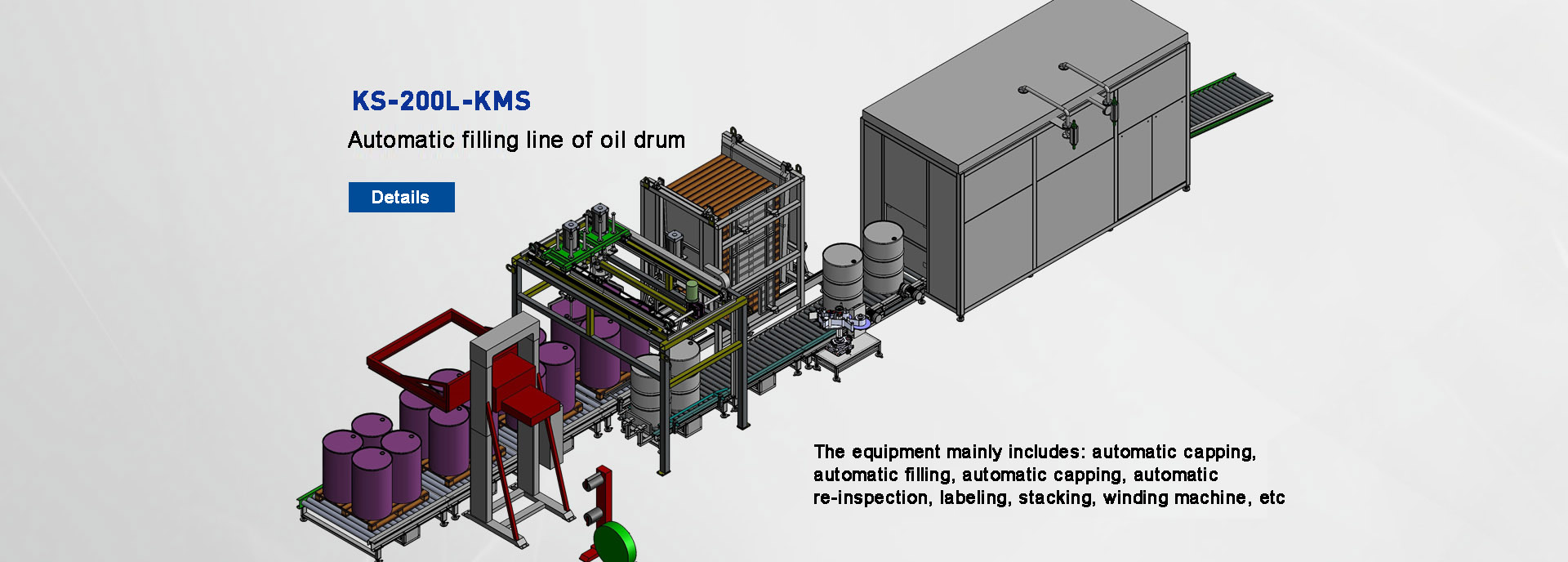

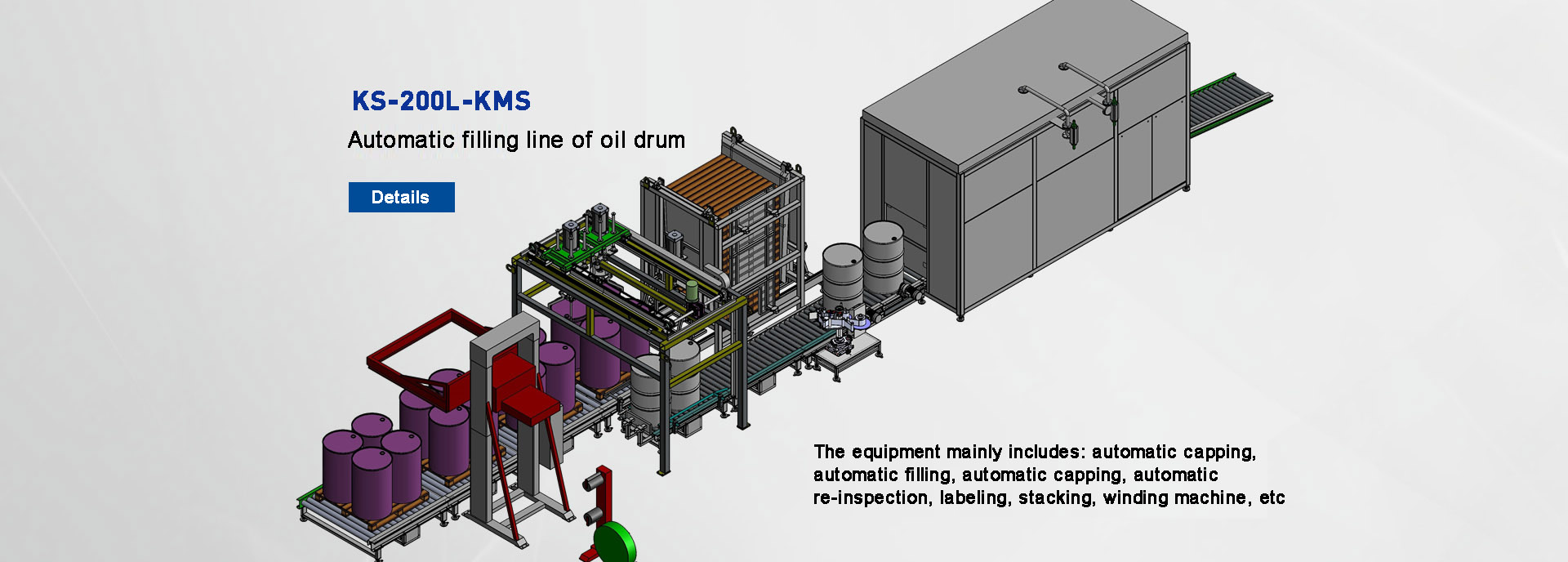

High-Speed Automatic Quad Drum Filler Smart Bulk Chemical Handling

High-Speed Automatic Quad Drum Filler & Smart Bulk Chemical Handling System

Key Features

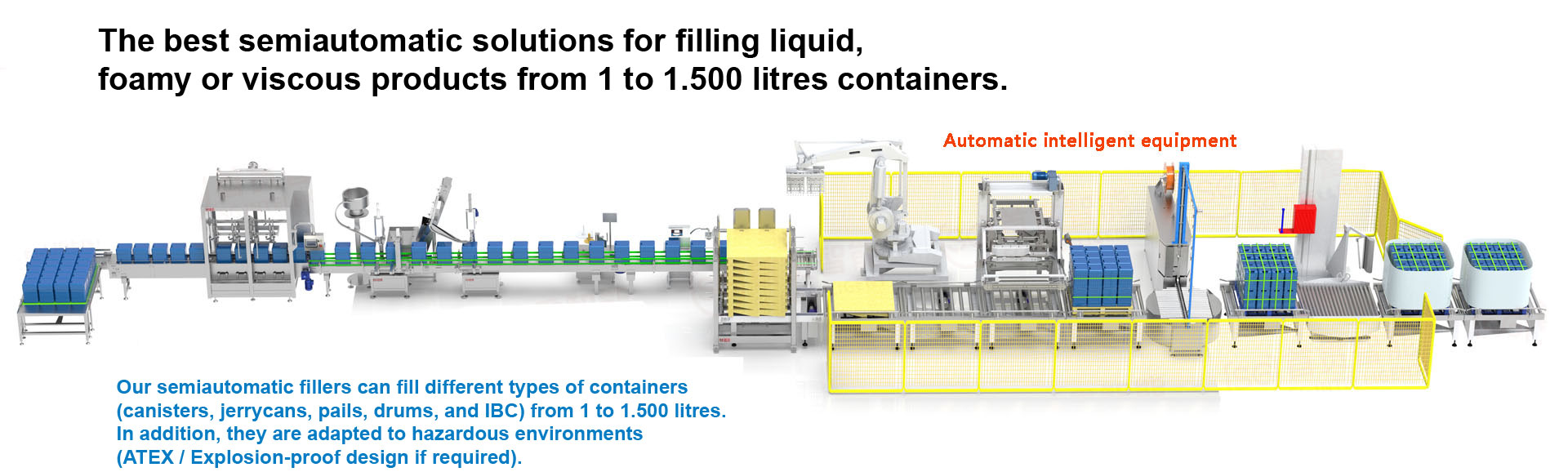

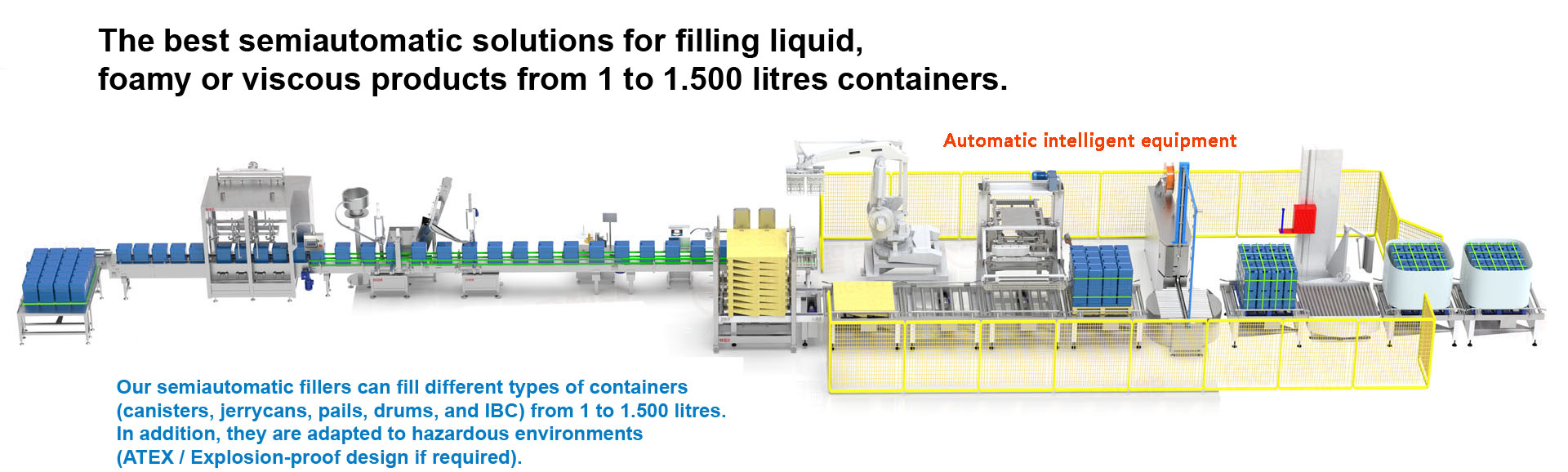

Quadruple Simultaneous Filling

4 Independent Stations: Fill up to 4 drums (e.g., 200L) simultaneously, reducing cycle time by up to 75% compared to single-station systems.

Dual-Mode Compatibilitye777乐彩线路检测: Automatically switches between drums, IBCs, and totes without manual intervention.

Smart Automation & AI Integration

AI-Powered Calibration: Adapts fill speed, volume, and nozzle positioning based on product viscosity, temperature, or container type.

IoT Connectivitye777乐彩线路检测: Real-time remote monitoring, data logging, and predictive maintenance alerts via cloud integration.

Touchscreen HMIe777乐彩线路检测: Intuitive interface for programming fill parameters, saving recipes, and tracking batch history.

No-Spill Precision Filling

Self-Sealing Nozzles: Pneumatic or servo-actuated nozzles prevent drips and spills during filling and after disengagement.

Gravimetric Mode: ±0.1% accuracy for critical applications (e.g., chemicals, pharmaceuticals) using real-time weighing.

Volumetric Modee777乐彩线路检测: Preset volume dispensing for consistent results in less critical applications.

Material Versatility & Durability

Stainless Steel Constructione777乐彩线路检测: 304/316 grade stainless steel for corrosion resistance in aggressive environments.

Hose & Seal Optionse777乐彩线路检测: PTFE, Viton, FKM, and NBR materials for compatibility with acids, solvents, bases, and high-viscosity fluids.

Optional Hastelloy/Titanium Upgrades: For extreme chemical resistance (on request).

Safety & Environmental Protection

Static Grounding & ESD Protectione777乐彩线路检测: Safe for flammable or explosive environments.

Vapor Extraction Arme777乐彩线路检测: Captures fumes at the fill point, directing them to a scrubber or ventilation system.

ATEX/IECEx Certification: Available for hazardous atmospheres (on request).

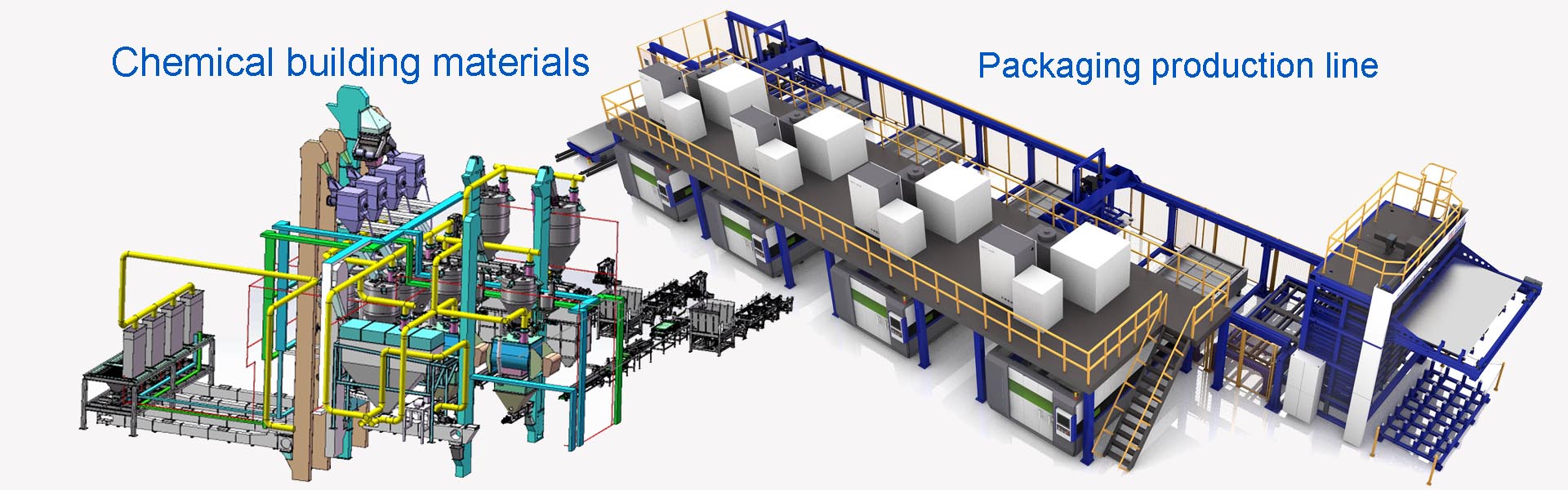

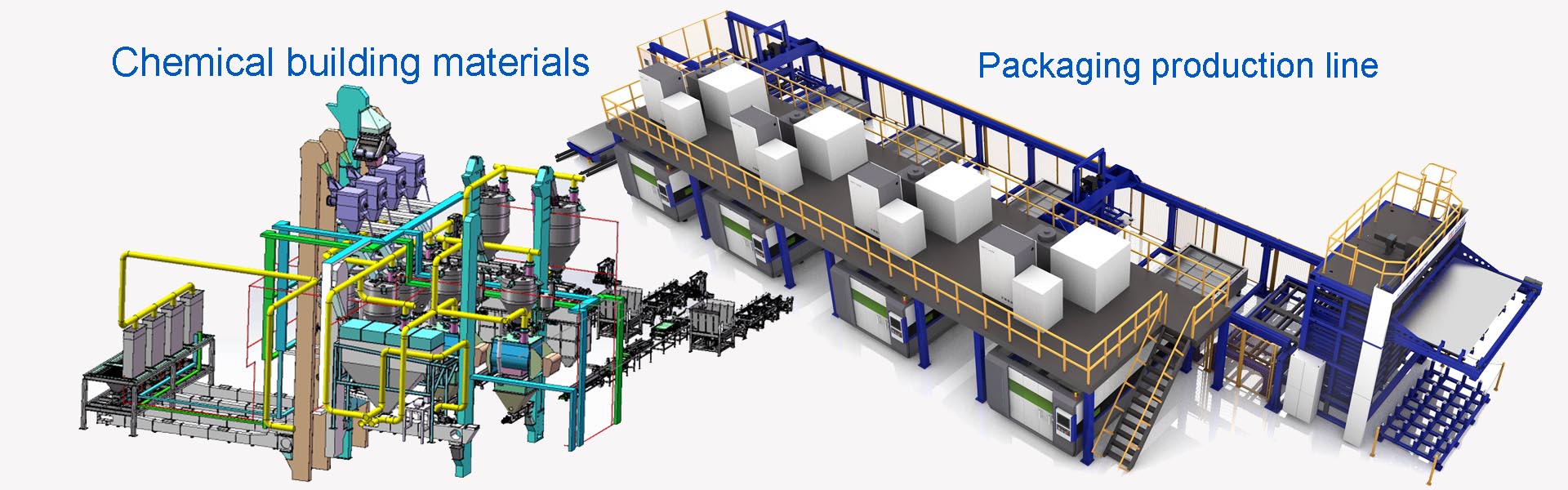

Bulk Chemical Handling Capabilities

Integrated Pump Systems: High-flow diaphragm pumps or centrifugal pumps for bulk transfer of chemicals.

Nitrogen Blanketing: Prevents oxidation or contamination for oxygen-sensitive products.

Inert Gas Purge: Option to purge containers with inert gas before or during filling.

How It Works

Container Placemente777乐彩线路检测: Operator positions drums, IBCs, or totes under the filling nozzles (automated positioning available as an option).

Smart Fillinge777乐彩线路检测: The machine dispenses the preset weight or volume of liquid, using AI to adapt to changing conditions.

No-Spill Cutoff: Nozzles automatically close at the correct level to prevent overfilling.

Vapor Extraction: Fumes are captured and directed to a scrubber or ventilation system.

Completion Alerte777乐彩线路检测: LEDs, alarms, and/or HMI notifications indicate filling is complete.

Benefits

Unmatched Productivitye777乐彩线路检测: Simultaneous filling of multiple containers reduces labor and cycle time by up to 75%.

Regulatory Compliance: Gravimetric accuracy ensures precise batch weights, minimizing giveaway and ensuring compliance with industry standards.

Operator Safety: No-spill technology, static grounding, and fume extraction protect against spills, leaks, and harmful vapors.

Flexibilitye777乐彩线路检测: Suitable for a wide range of liquids, including chemicals, solvents, oils, and viscous products.

Data-Driven Insightse777乐彩线路检测: IoT connectivity enables remote monitoring and predictive maintenance, reducing downtime.

Industry Applications

Chemical Manufacturing: Acids, solvents, bases, and specialty chemicals.

Petrochemicalse777乐彩线路检测: Fuels, oils, and lubricants.

Pharmaceuticalse777乐彩线路检测: APIs, bulk actives, and intermediates.

Food & Beverage: Syrups, oils, and high-viscosity ingredients.

Industrial Coatingse777乐彩线路检测: Resins, thinners, and adhesives.

Customization Options

Filling Systeme777乐彩线路检测: Choose between volumetric, gravimetric, or hybrid systems.

Materials: Stainless steel, Hastelloy, or other corrosion-resistant alloys.

Certificationse777乐彩线路检测: ATEX, ISO, and CE compliance for hazardous environments.

Additional Features:

Nitrogen blanketing for oxygen-sensitive products.

Data logging for traceability and batch reporting.

e777乐彩线路检测Integration with conveyors, palletizing systems, or labeling machines.

Why Choose This Machine?

Next-Level Accuracy: Gravimetric filling ensures precision, reducing product waste and ensuring batch consistency.

Safety First: No-spill technology, static grounding, and fume extraction minimize risks in hazardous environments.

Future-Proof Designe777乐彩线路检测: Scalable, modular, and upgradeable to adapt to evolving needs.

Corrosion Resistancee777乐彩线路检测: Stainless steel and optional Hastelloy construction ensure longevity in aggressive environments.

Supplier Considerations

Choose a supplier with:

Expertise: Proven experience in chemical, petrochemical, and industrial applications.

Customization Capabilities: Ability to tailor the machine to your specific needs.

Support: Installation, training, maintenance, and spare parts availability.

Certificationse777乐彩线路检测: ATEX, ISO, and CE compliance for safety and quality assurance.

The High-Speed Automatic Quad Drum Filler & Smart Bulk Chemical Handling Systeme777乐彩线路检测 is designed for high-performance liquid packaging operations. With its precision, safety features, and scalability, it’s the ideal solution for industries requiring reliable, efficient, and compliant filling of drums, IBCs, and totes. Whether you’re handling corrosive chemicals, volatile solvents, or viscous liquids, this machine ensures optimal productivity, operator safety, and regulatory compliance.

Immediate Order:

Website: http://fmnbp.org/product/drumfillingmachines-en.html

Alibaba:

e777乐彩线路检测China Manufacturing Co Ltd.:

-

Stone Powder packaging machine Dual Head packaging machine[2025-07-08]

-

Automatic Drum Filling Machine Barrel & IBC Filling Equipment High-Precision Engine OilLubricant Filling System[2025-05-29]

-

25kg valve bag Fertilizer packaging machine How to reduce production costs[2025-06-30]

-

200L Semi-Automatic Chemical Filling Machine Electric PLC Liquid Soap Fills Barrel Paper Metal Wood Packaging Used Condition[2025-04-18]