Bucket Paint Filling Machine Semi Automatic and Automatic Paint Filling Systems 2

Bucket Paint Filling Machine: Semi-Automatic & Automatic Systems

Overview

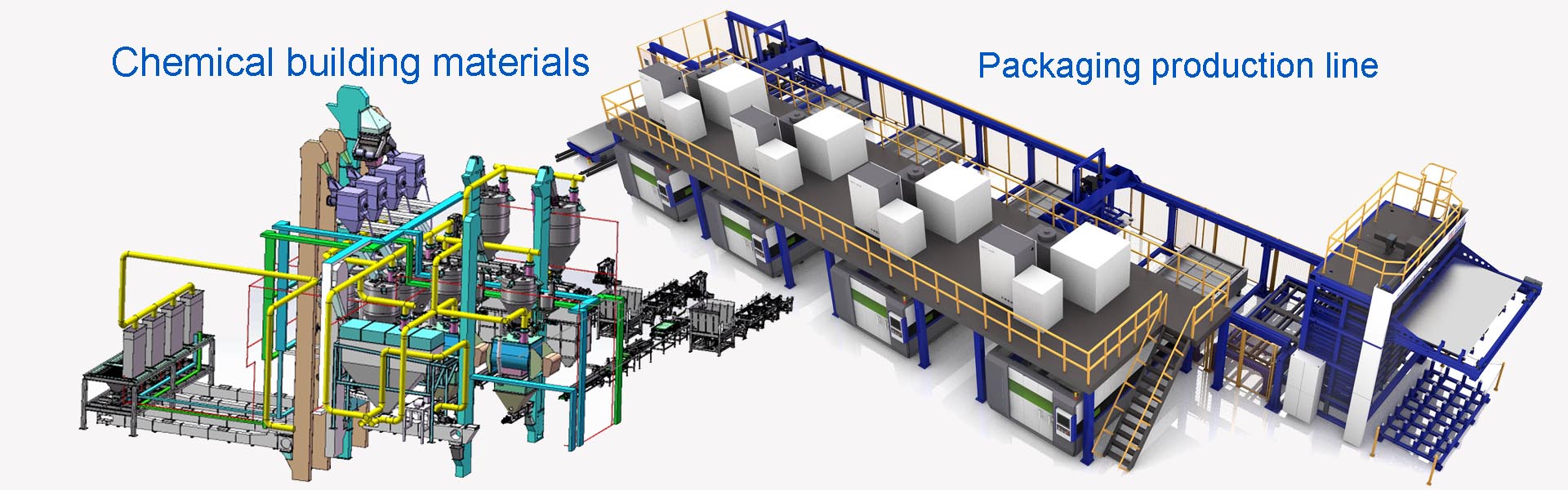

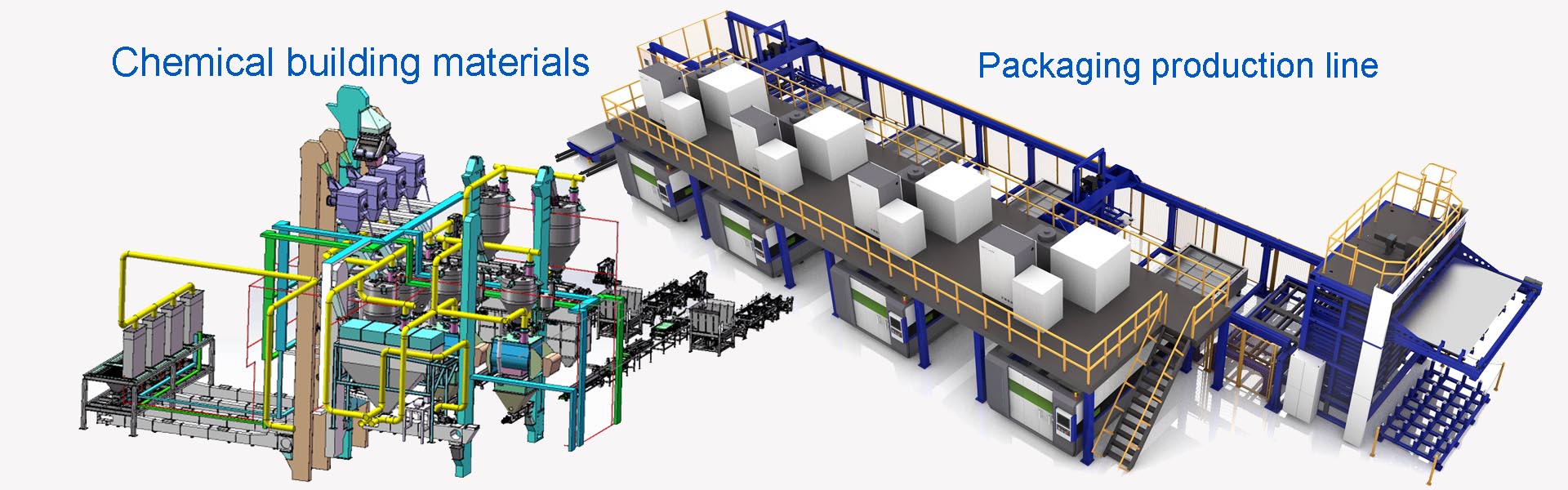

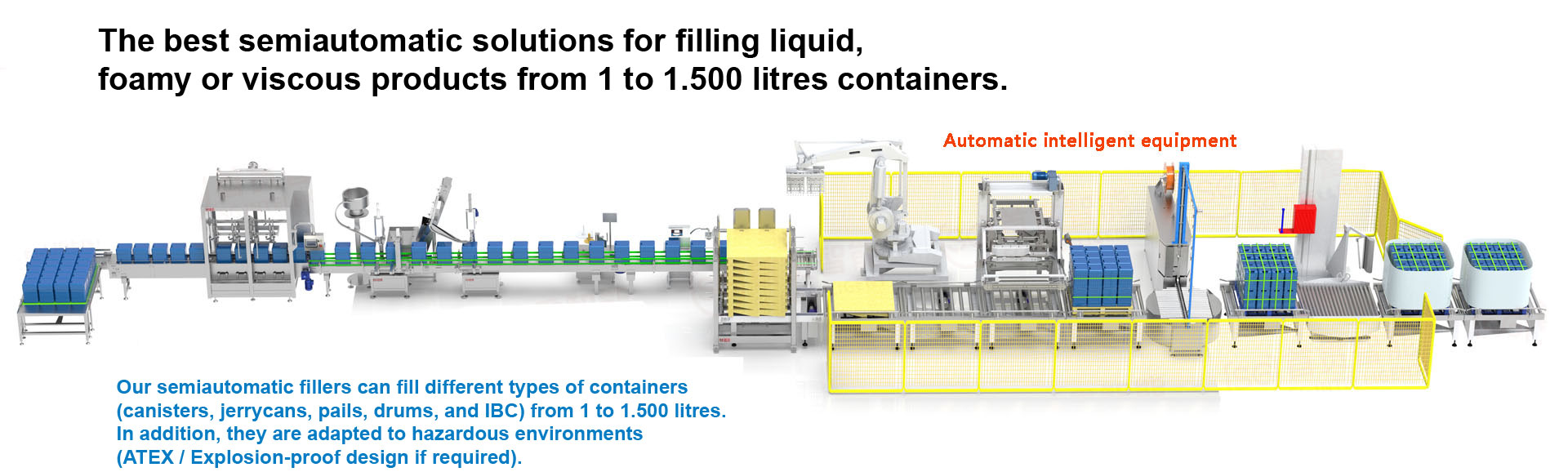

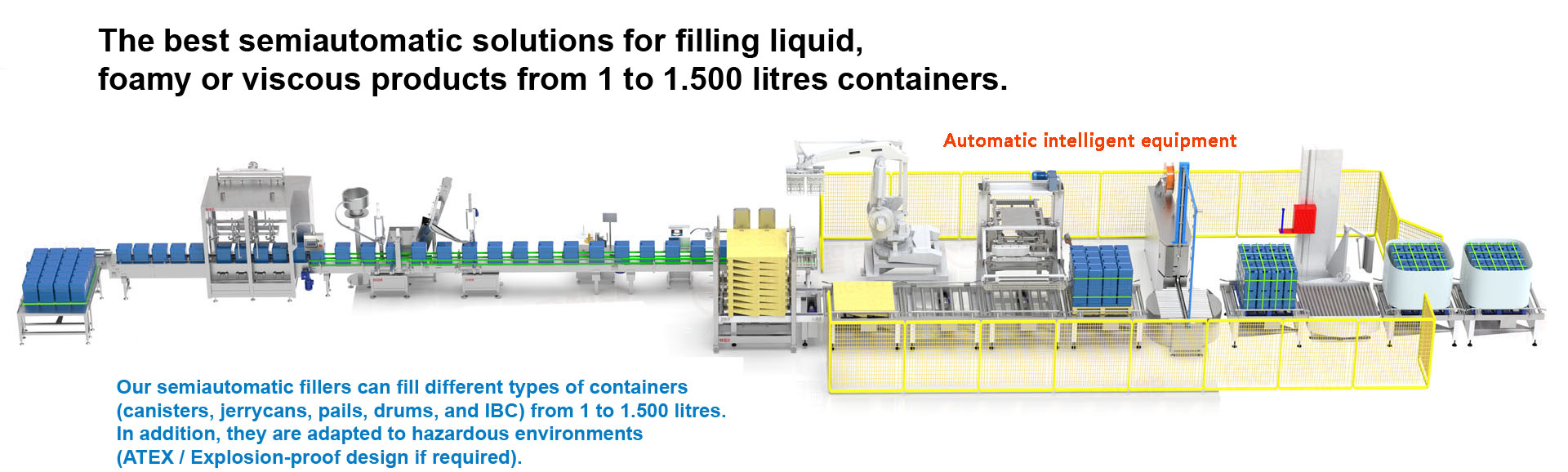

The Bucket Paint Filling Machine is designed for efficient, precise, and safe filling of paints, coatings, adhesives, and other viscous liquids into buckets (5L to 30L). Available in both semi-automatic and fully automatic configurations, these systems cater to small-scale operations or high-volume production lines. They ensure accurate fill levels, minimize product waste, and comply with safety standards for hazardous materials.

System Options

1. Semi-Automatic Paint Filling Machine

Operatione777乐彩线路检测: Manual loading/unloading of buckets; automated filling.

Key Features:

Precision Filling: ±0.5% accuracy via flow meters or weight cells.

Adjustable Speed: Controlled filling to prevent foaming or splashing.

Nozzle Design: Drip-free nozzles reduce spillage and mess.

Viscosity Handlinge777乐彩线路检测: Suitable for medium-to-high viscosity liquids (e.g., paints, adhesives).

Safetye777乐彩线路检测: Spill containment trays, emergency stop buttons, and ATEX options for flammable environments.

Ideal Fore777乐彩线路检测: Small to medium-scale operations, contract manufacturers, or startups.

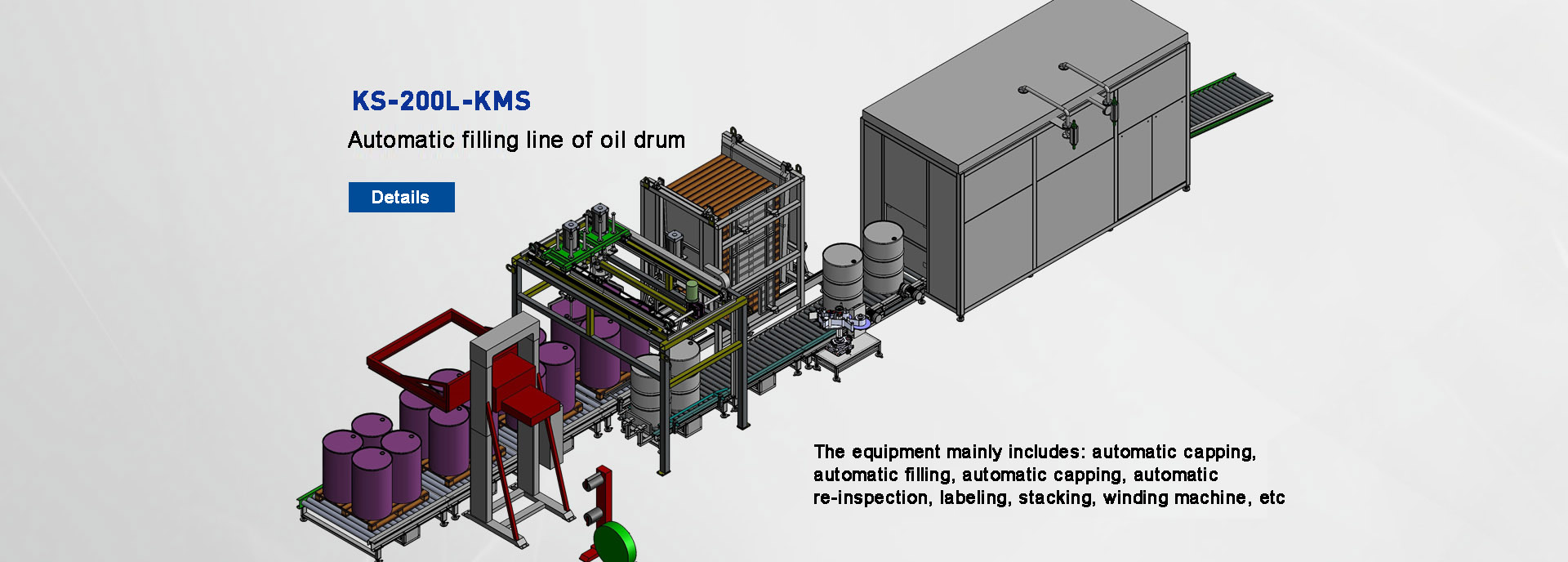

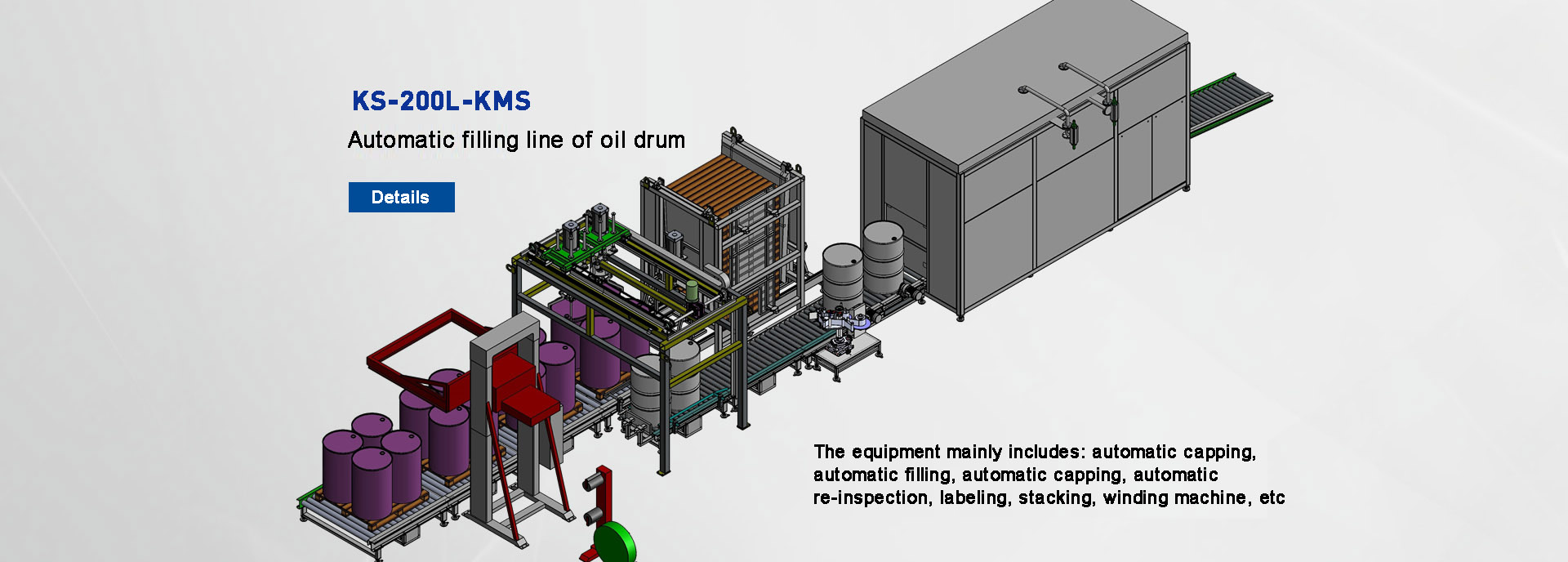

2. Fully Automatic Paint Filling System

Operatione777乐彩线路检测: Integrated conveyor, automated bucket indexing, filling, and capping.

Key Features:

High Throughput: Up to 15-20 buckets per minute (depends on viscosity).

Touchscreen HMIe777乐彩线路检测: Programmable for multiple bucket sizes, fill volumes, and products.

Automated Lidding: Optional press-on lid sealing or crimping.

Viscosity Management: Heated hoppers or pumps for temperature-sensitive paints.

Nitrogen Blanketing: Prevents foaming, oxidation, or contamination.

Weight-Based Filling: Load cells for density-variable products.

Cleaning: CIP (Clean-in-Place) or quick-release nozzles for easy maintenance.

Ideal For: Large-scale production, high-volume manufacturers, and industrial facilities.

Key Benefits

Accuracy: Ensures consistent fill levels, reducing overfill/underfill and product waste.

Speede777乐彩线路检测: Automated systems handle up to 15+ buckets per minute, boosting productivity.

Safety: Drip trays, fume extraction, and ATEX/IECEx certifications for hazardous areas.

Versatilitye777乐彩线路检测: Compatible with various bucket sizes (5L to 30L) and materials (plastic, metal).

Customization: Options for nitrogen blanketing, heated hoppers, and RFID tracking.

Compliance: Meets OSHA, ISO, and industry standards for paint and chemical handling.

Applications

Paints & Coatingse777乐彩线路检测: Water-based, solvent-based, and specialty paints.

Adhesives & Sealants: High-viscosity industrial adhesives.

Oils & Lubricants: Engine oils, greases, and automotive fluids.

Chemicalse777乐彩线路检测: Solvents, thinners, and hazardous liquids.

Optional Features

Vacuum Filtration: Removes air bubbles or contaminants before filling.

Riser Rings: Minimizes splash and foaming during filling.

Barcode/RFID Tracking: Logs batch numbers, expiration dates, and traceability data.

Multi-Head Fillinge777乐彩线路检测: Parallel nozzles for higher throughput (up to 4x speed increase).

Chemical-Resistant Materialse777乐彩线路检测: Stainless steel (304/316L), Hastelloy, or PTFE coatings.

Automatic Palletizing: Seamless integration with robotic or manual palletizing systems.

Clean-in-Place (CIP)e777乐彩线路检测: Automated cleaning cycles for hygiene-critical applications.

How It Works

Bucket Placemente777乐彩线路检测: Manual (semi-auto) or automatic (conveyor) loading of buckets.

Filling Process:

e777乐彩线路检测The nozzle descends into the bucket.

e777乐彩线路检测A metering pump or mass flowmeter dispenses the precise volume of paint.

The nozzle retracts, and excess product is reclaimed (optional).

Sealinge777乐彩线路检测: Optional automated capping or lid pressing.

Discharge: Filled buckets move to downstream processes (e.g., labeling, palletizing).

Why Choose This System?

Reliability: Robust design with minimal maintenance requirements.

Scalabilitye777乐彩线路检测: Easily expandable for future production needs.

Expert Supporte777乐彩线路检测: Custom engineering, installation, and lifetime technical support.

Contact Us for a customized solution tailored to your specific paint filling needs!

Immediate Order:

Website: http://fmnbp.org/product/drumfillingmachines-en.html

Alibaba:

China Manufacturing Co Ltd.:

-

Automatic Capping and Weighing Filling Machine 18L Coupling Agent/Exhaust Gas Purification Liquid[2025-07-04]

-

Apple Sauce Packing Machine Tomato Ketchup Filling Machine[2025-06-07]

-

Multifunctional Automatic Metering Lubricant Filling Machine for 1-10L[2025-05-14]

-

Semi-Automatic Paint Tank Filling Equipment for Streamlined Production[2025-07-05]