Automatic 30L Weighing Filling and Capping Machine for Liquids

Automatic 30L Weighing, Filling, and Capping Machine for Liquids

Overview

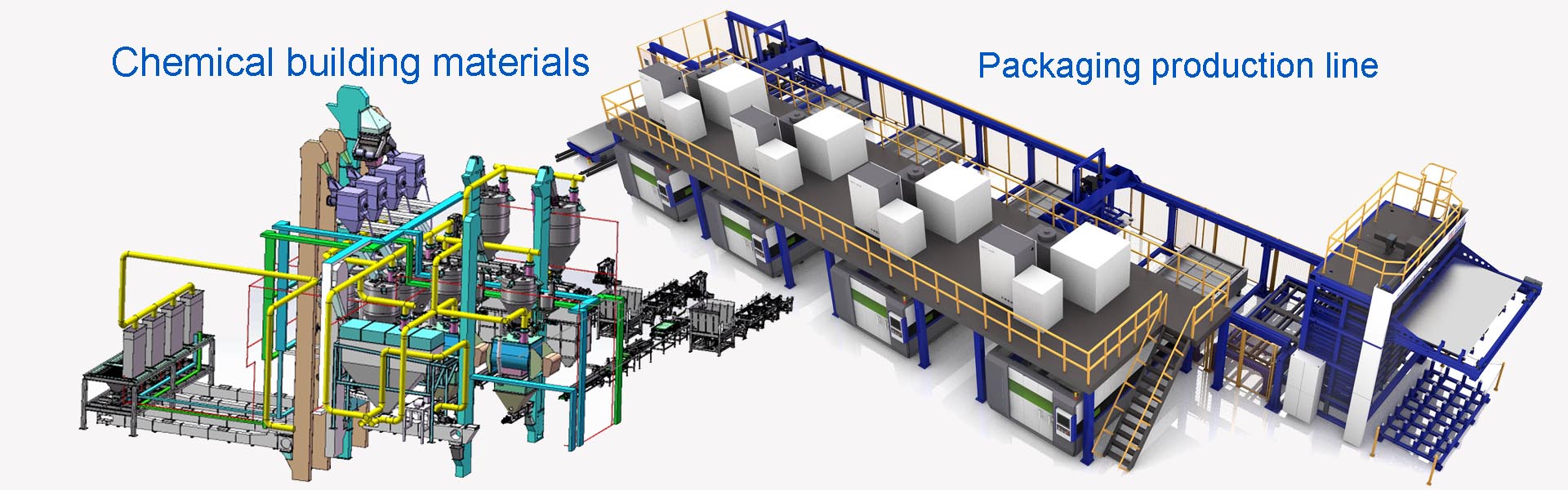

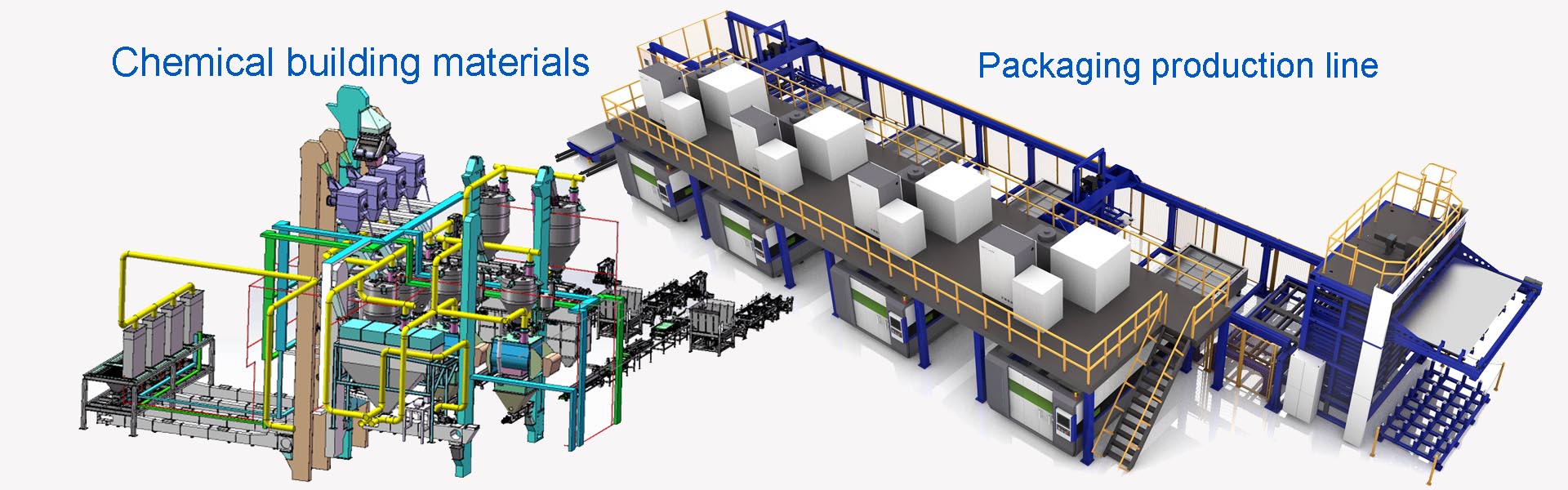

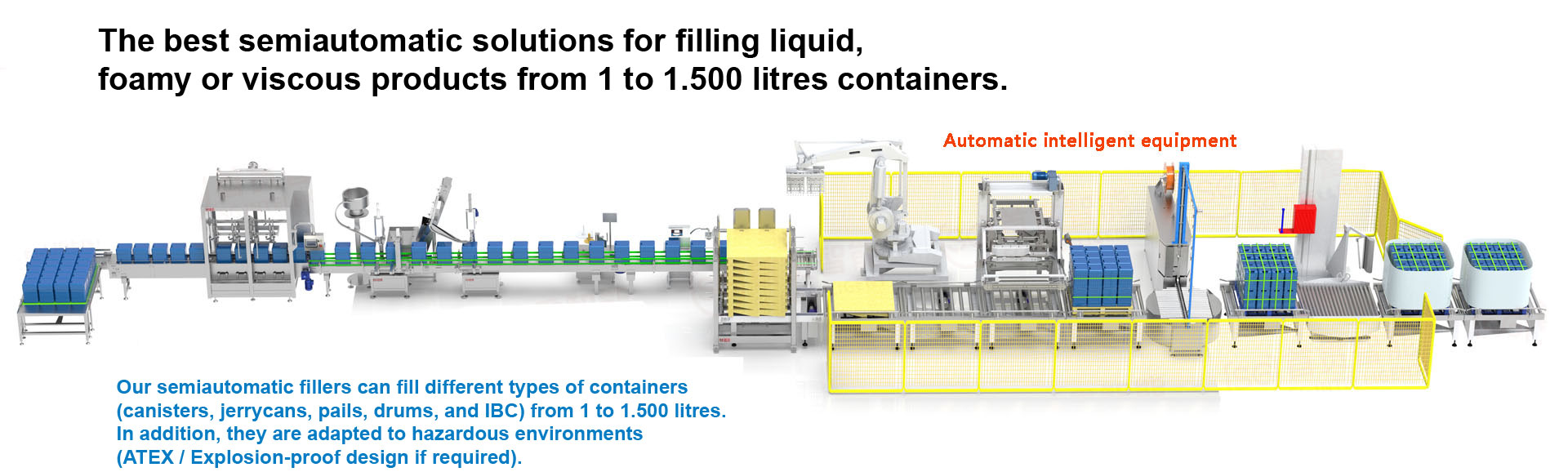

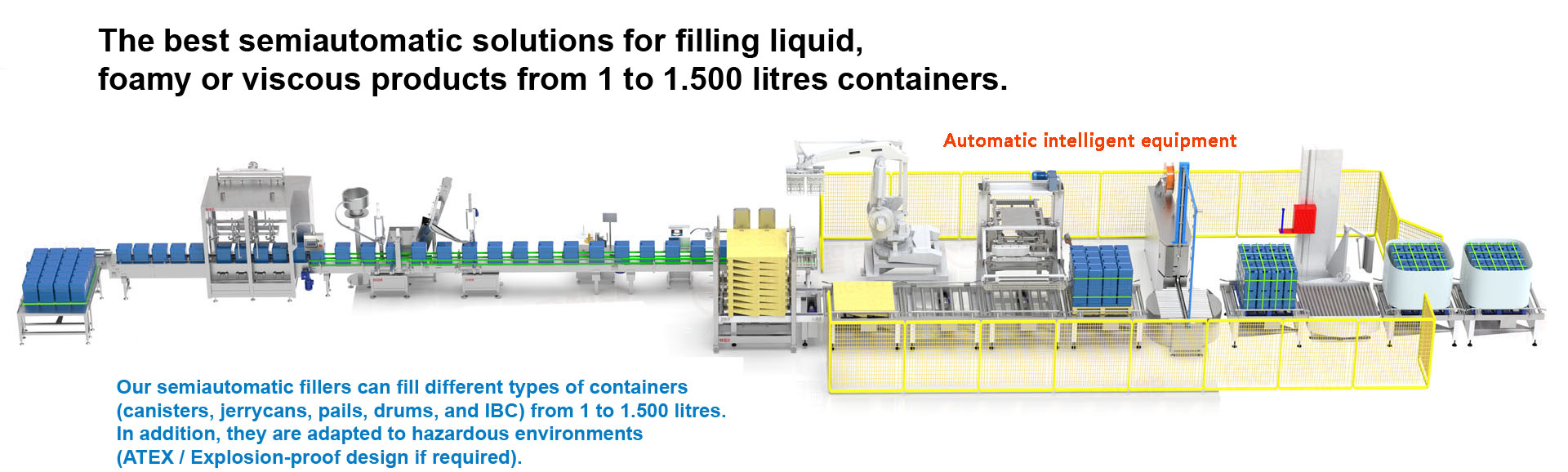

The Automatic 30L Weighing, Filling, and Capping Machine is a fully integrated solution designed for precise and efficient filling of liquids into 30-liter containers (jerrycans, pails, or drums). It combines weight-based accuracy, automated capping, and safety compliance to meet the needs of industries such as chemicals, food & beverage, pharmaceuticals, and industrial lubricants.

Key Features

1. Fully Automatic Operation

Touchscreen HMI:e777乐彩线路检测 Intuitive interface for program setup, volume adjustment, and real-time monitoring.

Integrated Conveyor System:e777乐彩线路检测 Automates container loading, indexing, and unloading.

Weighing Module:e777乐彩线路检测 In-line precision weighing (±0.1% accuracy) ensures target fill weight is met before capping.

Capping Mechanism: Automatically seals containers with screw caps, press-on lids, or crown seals.

2. High Precision & Speed

Filling Accuracy:e777乐彩线路检测 ±0.1%~0.2% (adjustable based on liquid viscosity and container type).

Flow Control: Servo-driven pumps or mass flow meters for precise liquid dispensing.

Production Speed:e777乐彩线路检测 Up to 600–1200 containers/hour (depending on configuration and liquid type).

3. Versatility & Flexibility

Container Compatibility:e777乐彩线路检测 Suitable for 5L to 30L containers (customizable for larger sizes).

Liquid Handling: Supports thin to medium-viscosity liquids (water-like, oils, detergents, etc.).

Adjustable Settings: Quick changeover for different volumes, container types, or cap styles.

4. Safety & Compliance

ATEX/IECEx Certified:e777乐彩线路检测 Safe for hazardous environments (Zone 1/21, ATEX Category 2/3).

Static Grounding: Automated earthing system to eliminate static spark risks.

Spill Prevention: Stainless steel drip trays and emergency stop buttons.

Materials:e777乐彩线路检测 304/316L stainless steel construction for durability and hygiene.

5. Advanced Technology

Weight-Based Filling: Real-time weighing ensures accurate fill weights, even with temperature or density variations.

Nitrogen Purge (Optional):e777乐彩线路检测 Inert gas purging to prevent foaming or oxidation during filling.

Data Logging:e777乐彩线路检测 USB/Ethernet export for batch tracking, traceability, and compliance reporting.

6. Ease of Use & Maintenance

Quick Changeover: Tool-free replacement of nozzles, capping heads, and conveyor guides.

Self-Cleaning: CIP (Clean-In-Place) functionality for hygienic applications.

Remote Support: IoT-enabled diagnostics for troubleshooting and software updates.

Applications

Industrial Chemicals:e777乐彩线路检测 Solvents, adhesives, thinners, and hazardous liquids.

Food & Beverage:e777乐彩线路检测 Edible oils, sauces, syrups, and bulk liquid foods.

Pharmaceuticals:e777乐彩线路检测 Non-hazardous liquid medications or APIs.

Lubricants:e777乐彩线路检测 Engine oils, greases, and industrial lubricants.

Household Products:e777乐彩线路检测 Laundry detergents, cleaning agents, and automotive fluids.

Optional Upgrades

Multi-Nozzle System: Increase throughput with 2+ filling heads.

Vision Inspection:e777乐彩线路检测 Cameras to verify fill levels, cap alignment, and label placement.

Labeling System: Inline date coding, batch number printing, or barcode scanning.

Robotic Handling:e777乐彩线路检测 Automated palletizing or depalletizing for larger operations.

Benefits

Precision & Consistency: Weight-based filling eliminates errors due to liquid density or temperature fluctuations.

Labor Efficiency: Fully automated process reduces manual intervention and labor costs.

Safety Compliance: ATEX certification and spill-proof design ensure hazardous environment safety.

Scalability: Modular design allows upgrades to multi-nozzle or fully integrated lines.

ROI:e777乐彩线路检测 High-speed operation and minimal downtime maximize production capacity.

Why Choose This Machine?

This machine delivers unmatched accuracy, speed, and safety for medium to large-scale liquid filling operations. Its ATEX certification, user-friendly interface, and versatility make it ideal for industries requiring reliable, compliant, and efficient packaging solutions.

Ready to streamline your liquid filling process?e777乐彩线路检测 Contact us for a customized quote, demo, or site assessment!

e777乐彩线路检测Immediate Order:

Website: http://fmnbp.org/product/drumfillingmachines-en.html

Alibaba:

e777乐彩线路检测China Manufacturing Co Ltd.:

-

High Speed Pneumatic Hand Wash Liquid Mouthwash Bottling Machine[2025-06-13]

-

Custom Liquid Filling Machine for Industrial Use Engineered for Oil, Paint, Detergent, and More 3.5 Gallon Bucket FILLER 3[2025-06-06]

-

Automatic Double Gun Filling Machine 5L Tank Oil Powder Beverage Chemical Plastic PET Packaging Electric Motor Gear PLC Bearing[2025-05-12]

-

Automatic Mouth-Finding Filling Machine Is Suitable for Ink Solvent/Polyurethane Filling[2025-05-13]