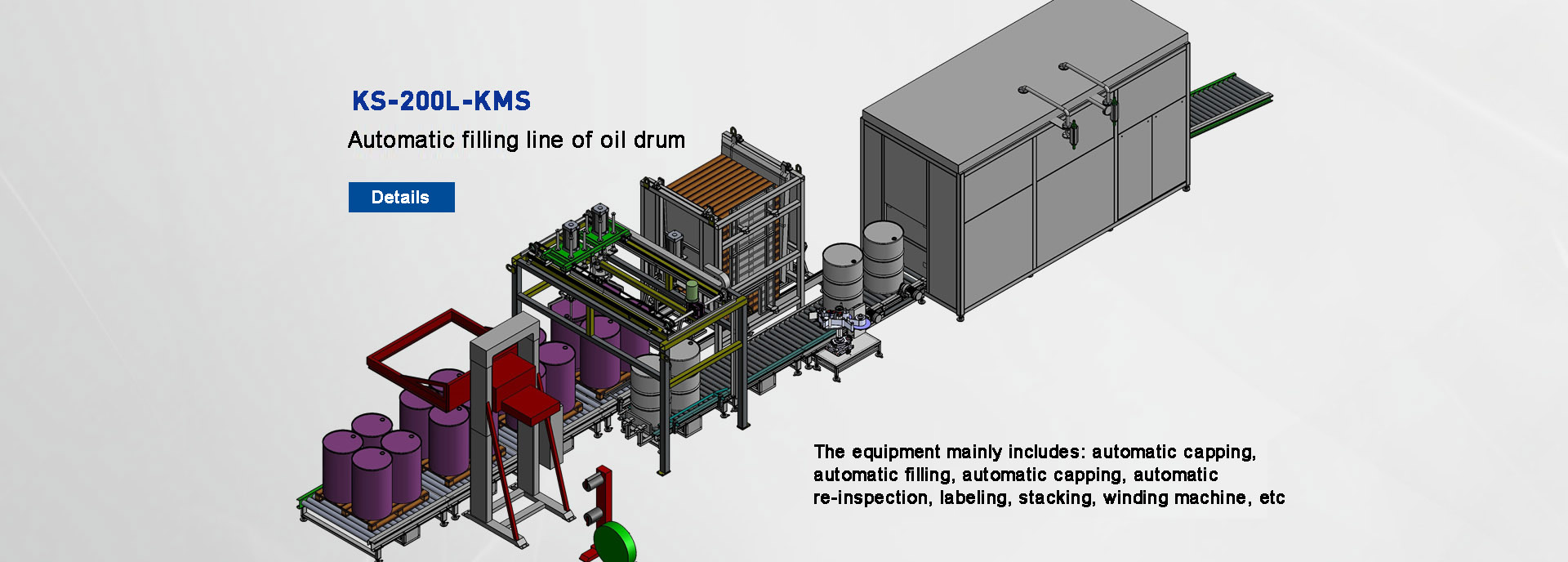

Weighing Filling Machine - 200KG Putty Filling System (1-to-1 Customized Filling Equipment Service)

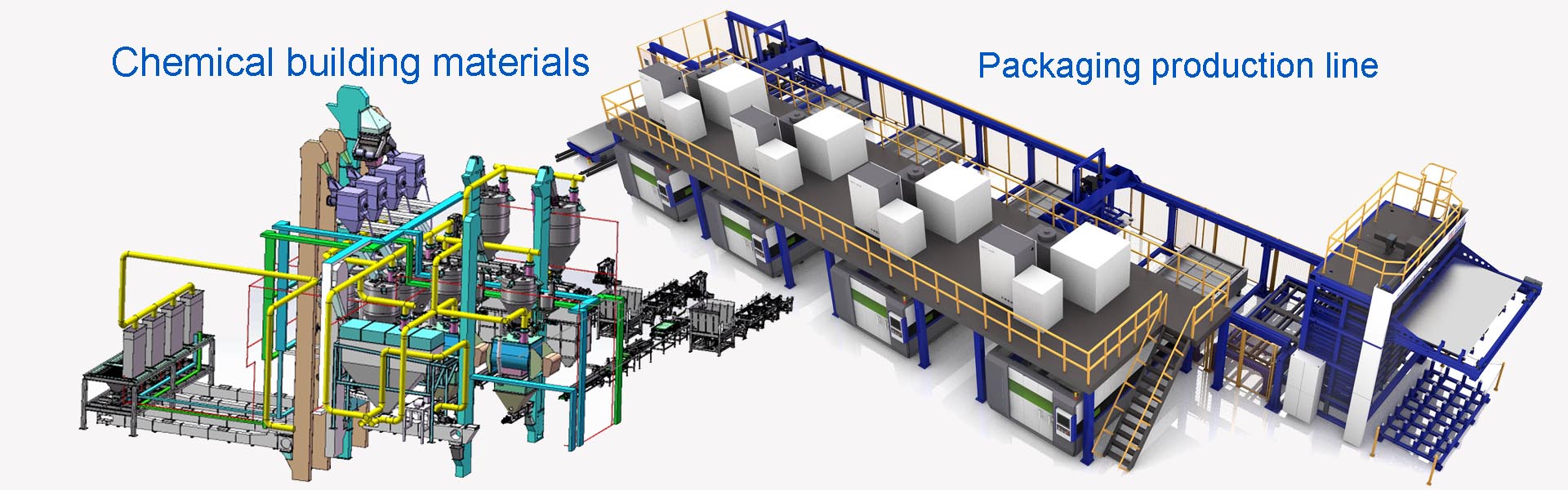

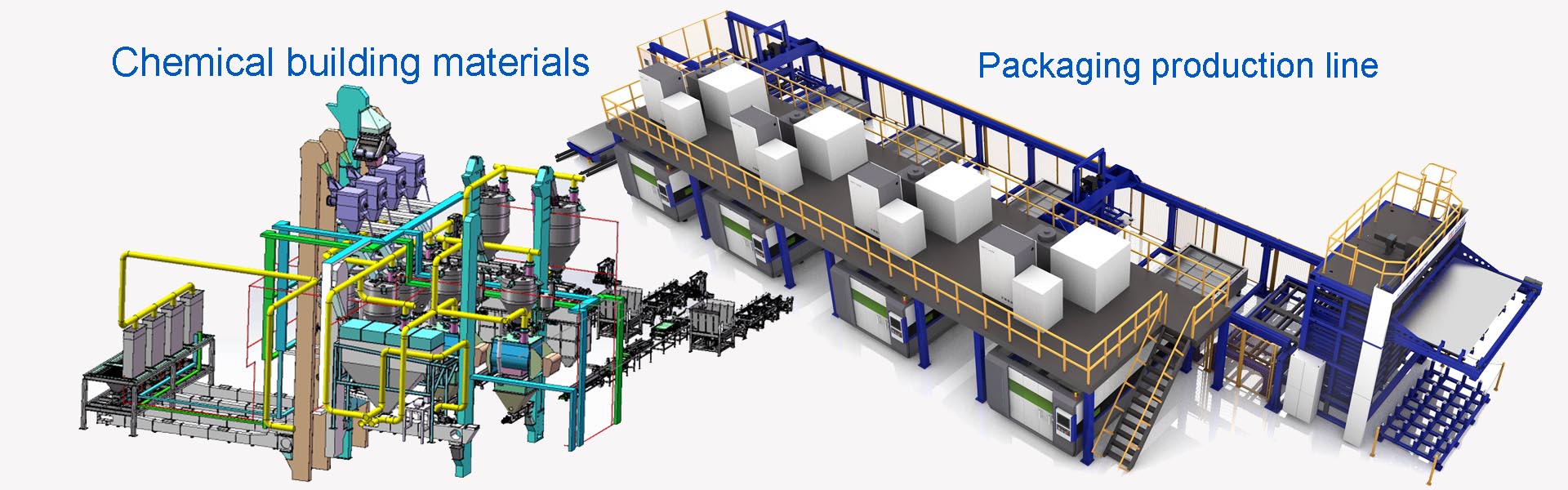

Shanghai Guangzhi Automation Equipment Co., Ltd. offers automated filling machines including acrylic emulsion fillers, paint fillers, liquid fillers, quantitative fillers, and manual fillers, known for their stable performance and user-friendly operation. We are committed to enhancing product quality and service standards while continuously meeting customer needs.

Weighing Filling Machine – 200KG Putty Filling System (1-to-1 Customized Filling Equipment Service)

Technical Parameters:

Filling Rangee777乐彩线路检测: 60–200 (kg/drum)

Power: 0.5 (kW)

Filling Speede777乐彩线路检测: 30–60 (drums/h)

Voltagee777乐彩线路检测: AC220V±10%, 50Hz

Filling Accuracy: ≤±0.2% (F.S.)

Air Consumption: 3–5 (m³/h)

Resolution: 50 (g)

Air Pressuree777乐彩线路检测: 0.4–0.6 (MPa)

Filling Heads: 1

Dimensions: 3800×1200×1650 (mm)

Explosion-Proof Rating: EX (d) II BT4

Drum Typee777乐彩线路检测: Compatible with various 200L drums

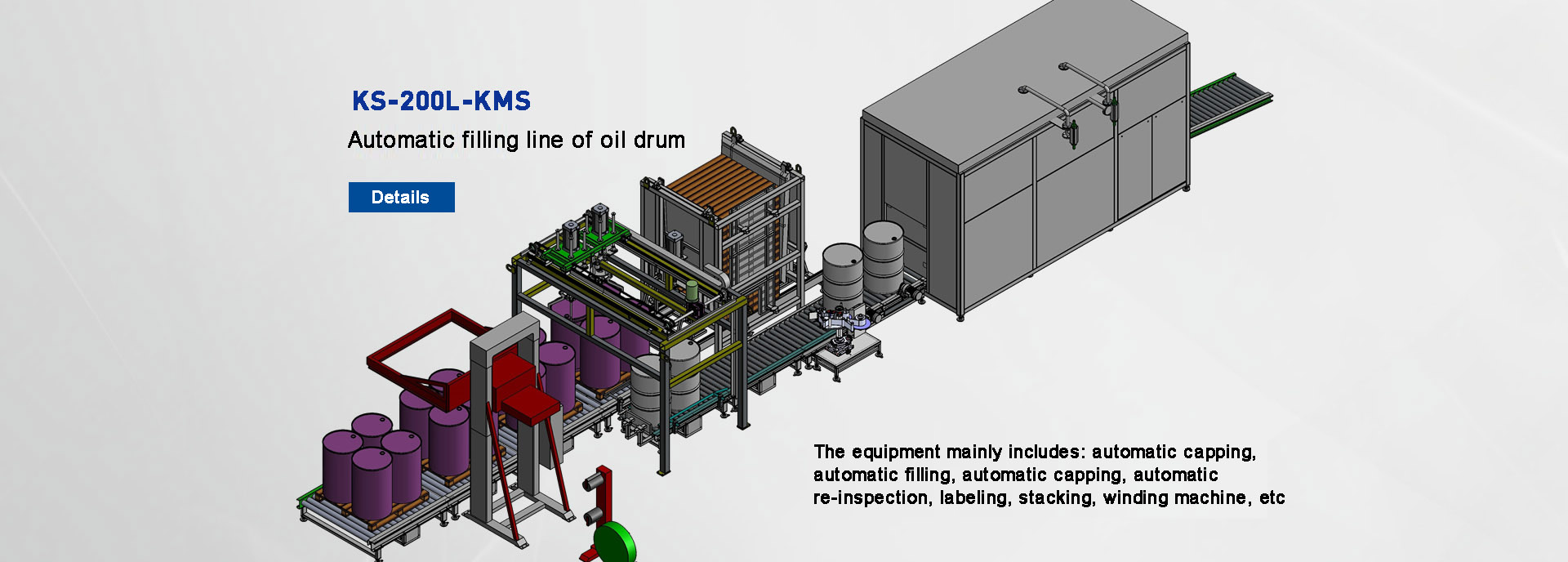

Key Features:

✔ Multi-Product Presets – Stores 20 different product weight settings for easy operation.

✔ Multi-Stage Filling – Two-stage (fast/slow) or three-stage (slow/fast/slow) filling for high precision.

✔ Leak Prevention – High-viscosity nozzles prevent dripping; low-viscosity nozzles include auto-drip cups & air hoods.

✔ Drum Protection – Prevents damage from misaligned drum positioning.

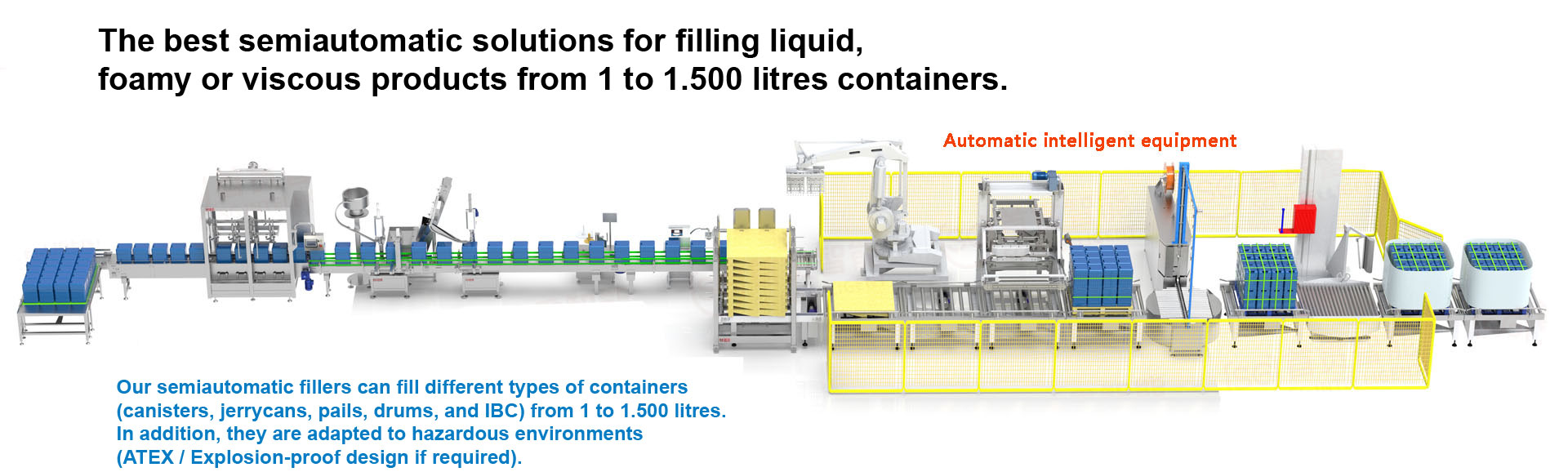

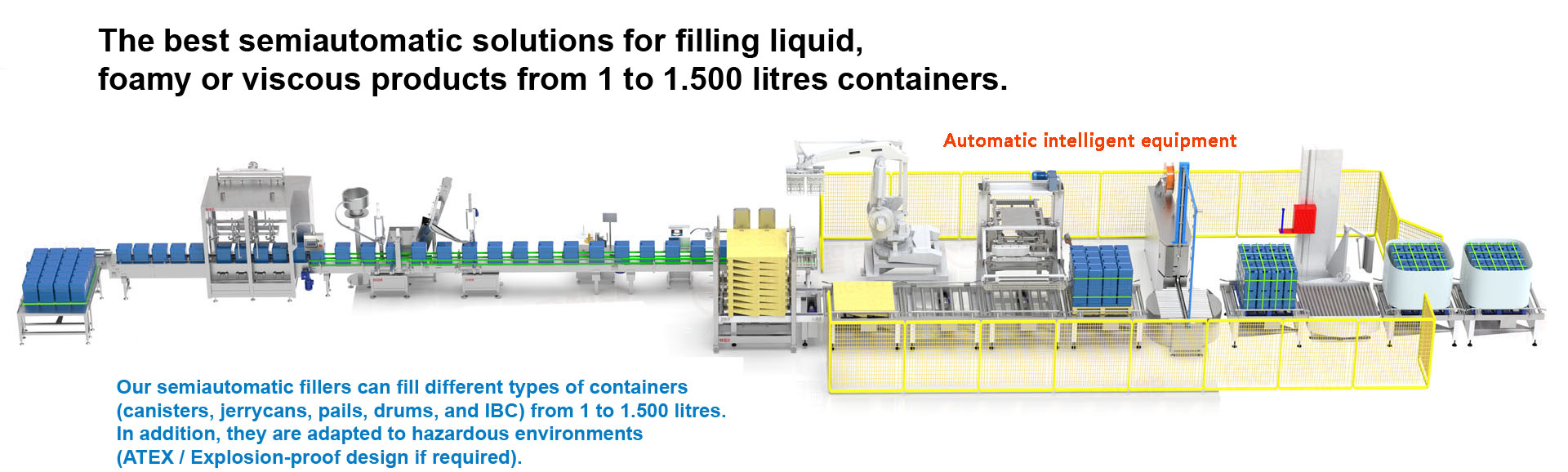

✔ Flexible Filling Modese777乐彩线路检测 – Top-fill, in-drum fill, below-surface fill, or above-surface fill for different materials.

Operation Process:

Manual Placement – Worker positions empty drum in loading zone; system auto-aligns with filling nozzle.

Auto-Filling – Nozzle inserts into drum, tares weight, and performs three-stage filling via ball valve.

Post-Fillinge777乐彩线路检测 – Nozzle retracts, drip tray engages, and filled drum moves to temporary storage.

Manual Cappinge777乐彩线路检测 – Worker secures lid.

Applications:

Ideal for liquids such as solvents, paints, resins, lubricants, inks, thinners, edible oils, and chemical fluids.

After-Sales Service:

Our filling machines are backed by a professional technical support teame777乐彩线路检测, ensuring low failure rates, easy maintenance, and long-term reliability to maximize production efficiency.

Related Equipment:

200KG Chemical Solvent Drum Filling Station (Explosion-Proof)

200L Glass Ink Filler (Submerged Nozzle Type)

100L Solvent Filler (Large-Scale Filling System)

200KG Water-Based Paint Filling Line (Explosion-Proof)

200L Varnish Conveyor (Auto-Palletizing)