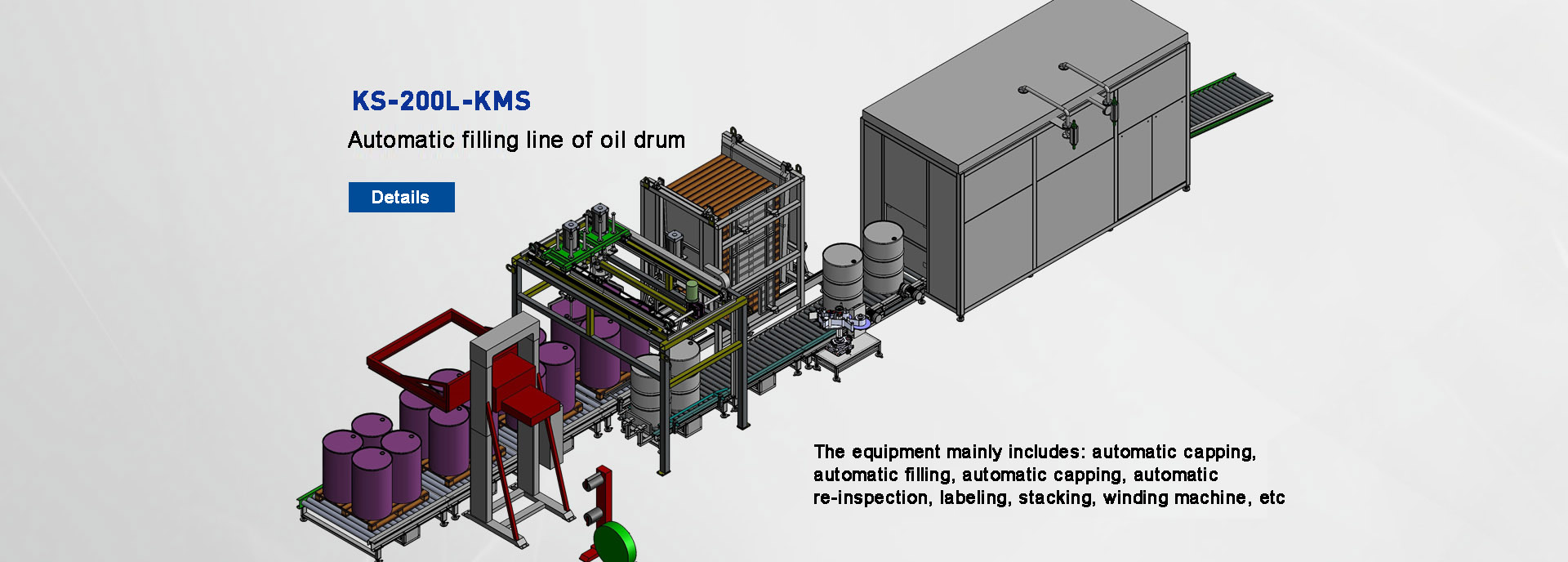

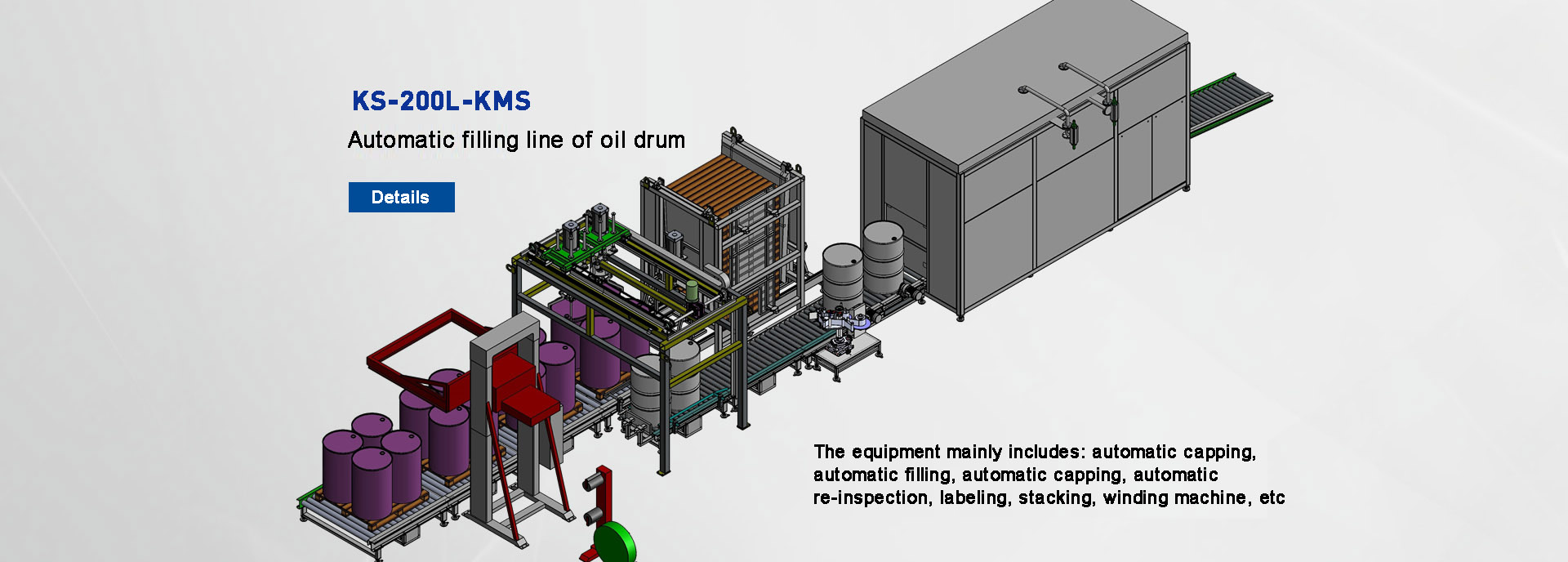

200L Automatic Measuring Filling Machine & Inkjet Ink Filling Machine - Providing Complete Automated Production and Filling Equipment

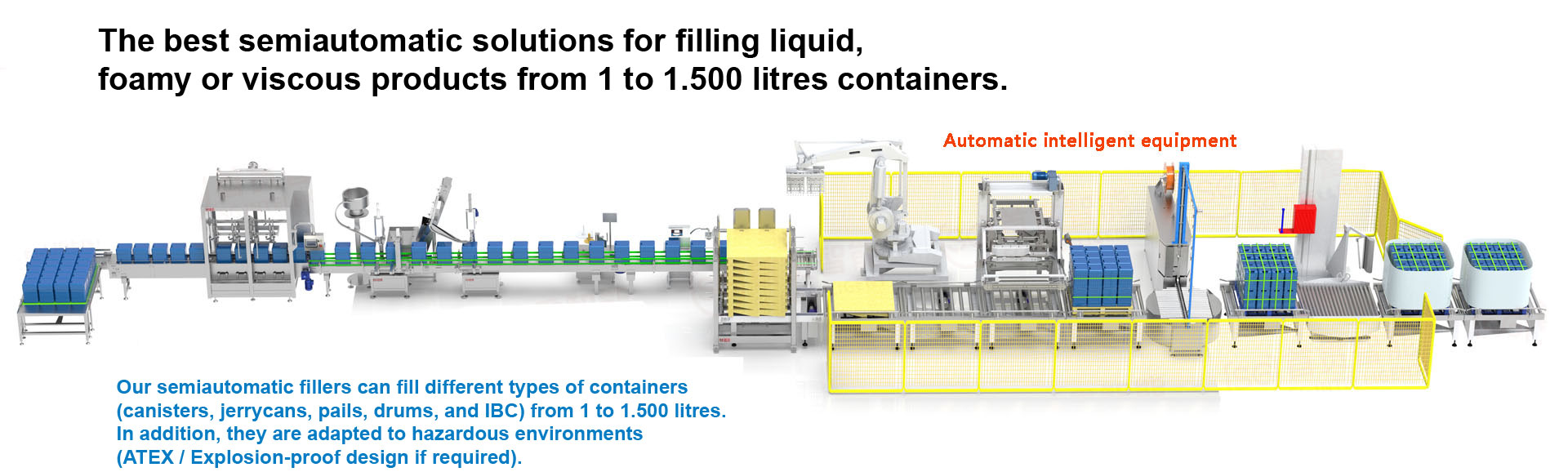

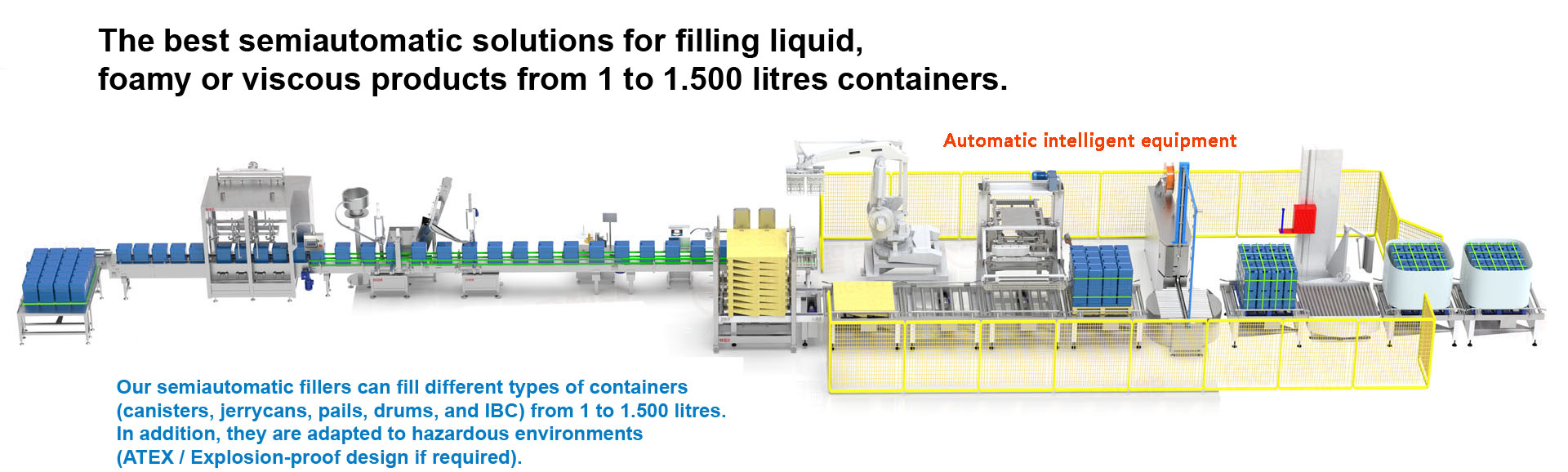

Shanghai Guangzhi Automation Equipment Co., Ltd.e777乐彩线路检测 specializes in the R&D and production of liquid , including hydrazine hydrate fillers, beverage fillers, round/square drum fillers, and compact filling machines. With extensive industry experience and advanced technology, we continuously meet customer demands while enhancing product quality and service standards.

200L Automatic Measuring Filling Machine & Inkjet Ink Filling System – Technical Specifications

Capacity: 60–200L

Max. Weighing: 300L

Sensitivity: 0.01L

Accuracy: ≤±0.1%

Speede777乐彩线路检测: 40–60 drums/hour (flow-dependent)

Nozzle Material: SUS304 stainless steel (SUS316L optional)

Drum Size: Ø1200×H1000mm

Power: AC220V/50Hz

Air Pressuree777乐彩线路检测: 0.4–0.8MPa

Operating Temp.e777乐彩线路检测: -10°C to 50°C

Explosion-Proof: No

Key Features

Auto Barrel Positioninge777乐彩线路检测 – Servo-driven nozzle alignment.

Patented Nozzle Designe777乐彩线路检测 – Fast, precise, and splash-free filling.

Dual-Speed Filling – Fast bulk fill + slow precision topping.

Safety Interlocks – Ensures operator and process safety.

Adjustable Speed – Flexible control via touchscreen.

Throughput: 6–10 tons/hour (material-dependent).

Weighing Range: 60–200kg.

Operation Process

Place empty drum on conveyor → manually open lid.

e777乐彩线路检测Start filling via HMI → nozzle auto-aligns.

Fast-fill → switches to slow-fill near target weight.

Stop at exact weight → manually seal and move to output zone.

Applications

✔ Pharmaceuticals ✔ Cosmetics ✔ Food ✔ Pesticides

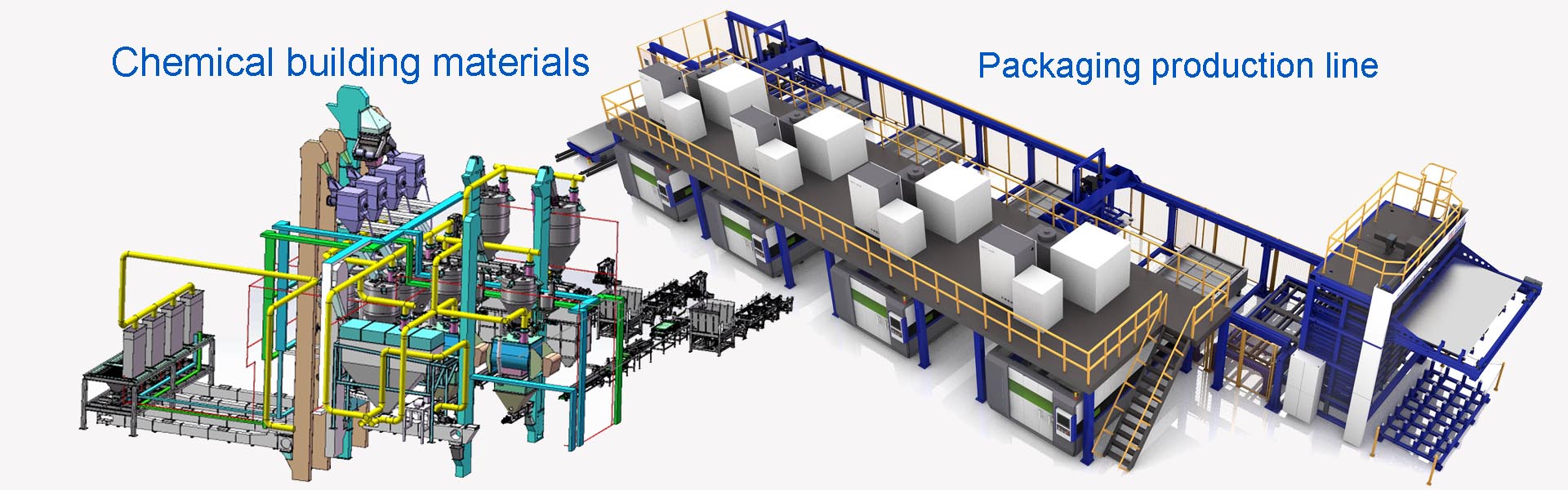

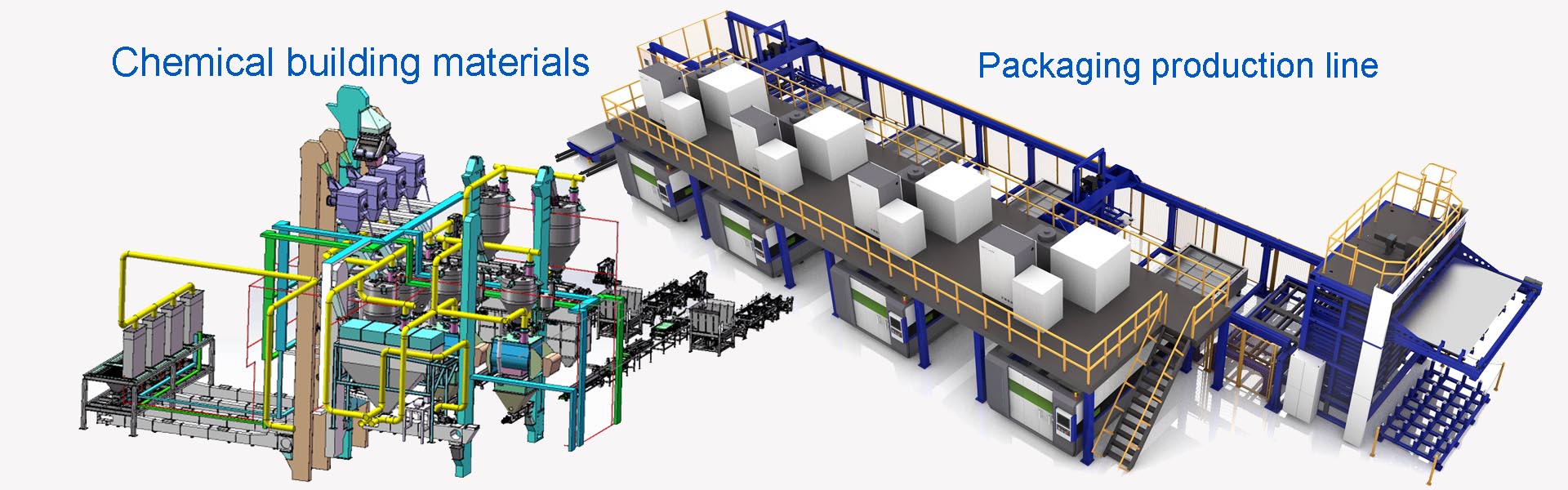

e777乐彩线路检测✔ Chemicals ✔ Petrochemicals ✔ Construction Materials

After-Sales Service

1-Year Warrantye777乐彩线路检测: Free repairs for non-human damage (parts + labor + travel).

On-Site Setupe777乐彩线路检测: Installation guidance & commissioning.

Traininge777乐彩线路检测: Hands-on operator training.

48-Hour Responsee777乐彩线路检测: Emergency support guaranteed.

Lifetime Supporte777乐彩线路检测: Discounted parts after warranty.

Spare Partse777乐彩线路检测: Immediate availability.

Related Equipment

e777乐彩线路检测300KG Polyester Filling Line

200L Semi-Auto Solvent Drum Filler

e777乐彩线路检测200KG PU Glue Capping Machine

e777乐彩线路检测200L Disinfectant Filler (Dual-Station)

e777乐彩线路检测208L Fertilizer/Pesticide Capper